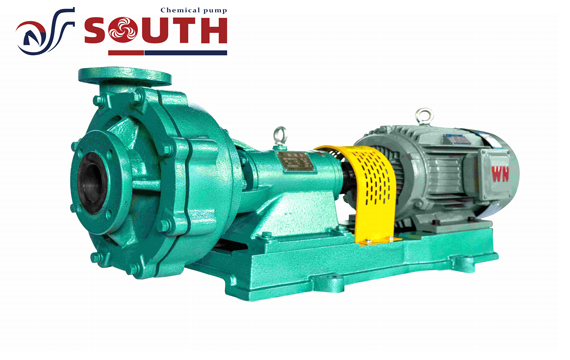

SOUTH CENTRIFUGAL PUMP FACTORY

Professional Centrifugal Pump Manufacturer

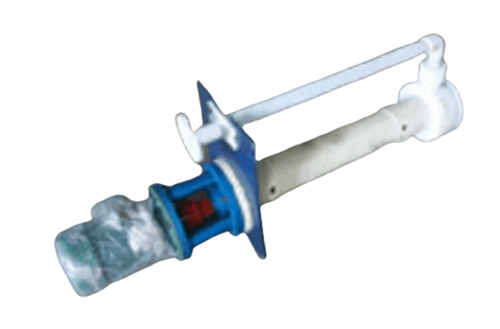

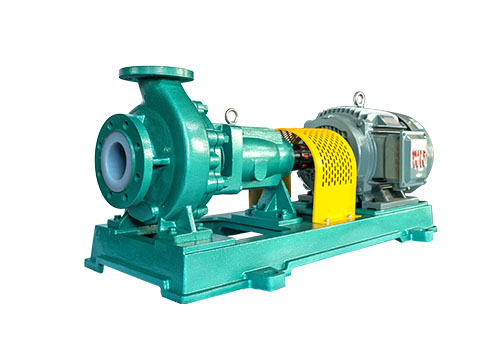

Single Stage Centrifugal Pump

Model: IHF-65-50-160

- Superior Corrosion & Abrasion Resistance: Fluoroplastic lining ensures extended service life.

-

High Temperature & Pressure Resistance: Reinforced with cast steel, suitable for demanding environments.

- Reliable Sealing: Advanced bellows mechanical seal for leak-free operation.

- Easy Maintenance: User-friendly design for quick disassembly and inspection.

- Efficient & Long-lasting: Outstanding performance for stable, long-term operation.

What is Centrifugal Pump

Industrial Centrifugal Pumps are powerful and versatile fluid transfer devices widely employed across numerous industries. These pumps utilize the centrifugal force generated by the rotation of their impellers to efficiently propel liquids from one point to another. The design of industrial centrifugal pumps encompasses robust materials capable of withstanding harsh environments and corrosive fluids, ensuring durability and longevity.

These pumps boast a wide range of applications, from chemical processing and oil refining to water treatment and power generation. They are designed to handle a diverse array of fluids, including clean water, sewage, acids, alkalis, and slurries, making them indispensable in many industrial settings.

The key features of industrial centrifugal pumps include their ability to deliver high flow rates and pressures, operate with low noise and vibration levels, and maintain excellent sealing performance to prevent leaks. Additionally, many modern industrial centrifugal pumps are equipped with advanced control systems and monitoring capabilities, enabling operators to optimize pump performance, detect potential issues, and reduce downtime.

Some product , if they are industry product, you can put ” What is xxx” as heading, and write some basic meaning and features of the product, but if this page is about service, and 100% commercial product, then heading can be ” Your Xxxx Manufacturer” or just put a “Brand name +product name” as headingLorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua. Quis ipsum suspend.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua. Quis ipsum suspend. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua. Quis ipsum suspend. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua. Quis ipsum suspend. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua. Quis ipsum suspend.

Centrifugal Pump by Features

Corrosion resistance, abrasion resistance, high temperature resistant, high mechanical strength, sealed performance is reliable.

Corrosion resistance, no leakage, simple operation, smooth operation, convenient maintenance, not aging, long service life.

Fill with liquid before first use and you can use it for life, with self-priming function, corrosion resistance, no leakage.

Seals and impellers are optional, corrosion-resistant and wear-resistant, and can transport media containing particles.

Fast heat dissipation, stable operation, good corrosion resistance, and resistance to highly mixed media. It does not require the removal of pipelines for maintenance, making maintenance easy.

Vertical centrifugal pump, depth of submerged up to 7 meters, wear resistance, no leakage, long service life.

Have self-lubrication function with low friction coefficient, high wear resistance, designed for conveying liquids contain corrosive and particle or crystallized mediums.

large flow capacity, low pump head. no leakage. stable operation, easy maintenance. pump materials are optional.

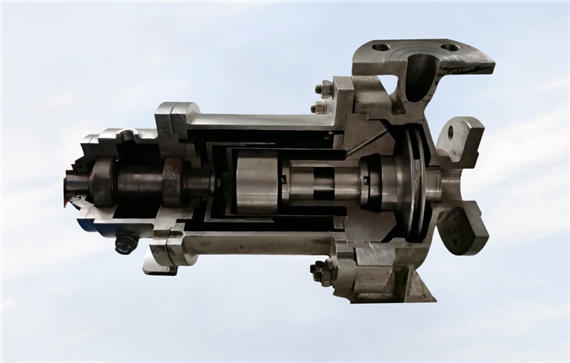

Working Principle Of Centrifugal Pump

The core components of a centrifugal pump include impeller, pump casing, pump shaft, bearings and seals. the motor converts electrical energy into mechanical energy and drives the impeller to rotate at high speed through the shaft transmission. impeller drives the medium in the pump casing to do centrifugal motion. Under the action of centrifugal force, the medium gains kinetic energy, thereby transporting the fluid.

Impeller

The basic function of the impeller is to convert mechanical energy into kinetic energy of the medium through rotation. when the impeller rotates, a vacuum is formed at the impeller inlet, and the medium is pushed in under atmospheric pressure. a high-pressure area is formed at the impeller outlet, and the medium is discharged. this cycle is repeated to complete the liquid transportation.

Pump casing

The main function of the pump casing is to evenly guide the liquid into the impeller. its material selection and internal design can effectively reduce the pressure fluctuation and noise of the pump, making the operation of the pump more stable, and can also adjust the flow rate of the pump.

Seals

The main function of seals is to prevent leakage of media in the pump and intrusion of external impurities. for example, mechanical seals achieve sealing by keeping the contact end faces of the dynamic ring and the static ring in contact during movement.

Pump shaft

The pump shaft is the main component for transmitting mechanical energy. It is connected to the motor through a coupling, transmitting the torque of the motor to the impeller, thereby driving the impeller to rotate.

Bearings

Bearings are mainly used to support and guide the pump shaft to ensure the smooth rotation of the pump shaft and impeller. the bearings in centrifugal pumps are usually sliding bearings with good wear resistance and long service life.

Lining Fluorine Plastic Chemical Centrifugal Pump

Pump casing, pump cover, impeller, and shaft sleeve all utilize fluorine lining technology. shaft seal adopts outside advanced bellows mechanical seal, import and export of pump adopts cast steel reinforcement.

Pump usage

Conveying different concentrations of sulfuric acid, hydrochloric acid, nitric acid and aqua regia, hydrofluoric acid, strong alkali, strong oxidizer, reductant, strong corrosive medium such as chlorine ion.

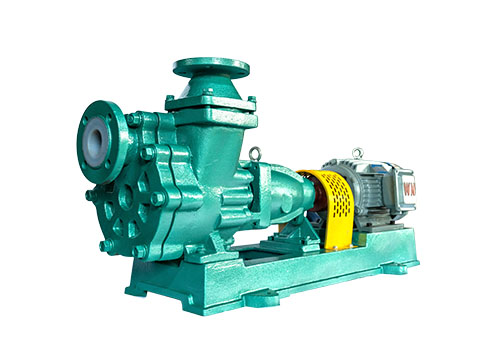

Fluorine Plastic Alloy Centrifugal Pump

Fluorine plastic alloy centrifugal pump is to use special pump manufacturing and processing technology, flow components are fluoroplastic and mechanical seals are used. this pump has two structural types: long bracket and short bracket.

Centrifugal Pump usage

Transporting different concentrations of acid, alkali, and highly corrosive media, can be resistant to all stainless steel to resist corrosion medium, applicable to biological medicine, petrochemical, sewage treatment and other industries.

Fluorine Plastic Lined-in Self-priming Centrifugal Pump

Fluorine-lined self-priming pump is a new generation of corrosion-resistant self-priming centrifugal pump improved on the basis of the traditional self-priming centrifugal pump. The self-priming height can reach 4 meters. If this pump equipped with non-return foot valve, it also could improve to 1-3 meters.

Self-priming Centrifugal Pump usage

Suitable for chemical industry level below the pump suction process, neutral or corrosive, low or high temperature (150℃), liquid solid particles content lower than 5%.

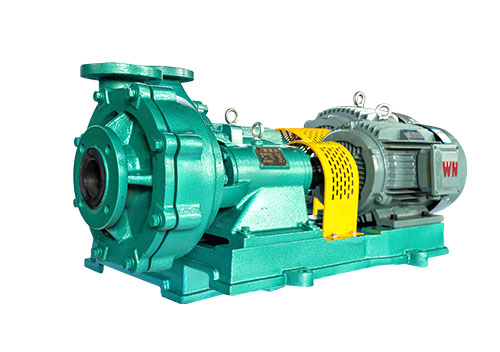

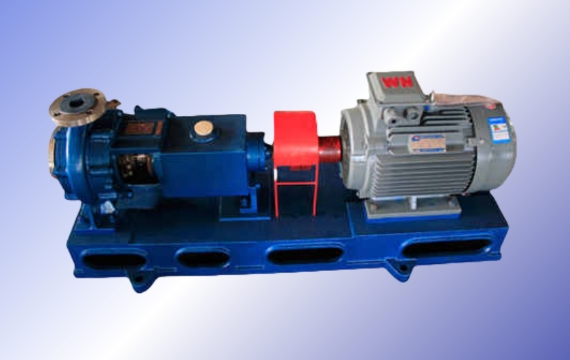

Stainless Steel Centrifugal Pump

It can be gland packing or mechanical seal chosen according to client’s request. mechanical seal can be choosing single(end)face, double(end)face, balanced face or imbalance face. impeller can be designed with open – type or semi – open type. It can transfer certain fiber or particle liquids .it is generally standard chemical centrifugal pump in fine chemical fields.

Stainless Steel Pump usage

Suitable for conveying clean or containing solid particles and fiber content, low temperature or high temperature, neutral or corrosive liquid. various temperature and concentration of alkaline solution, various salt solution, all kinds of liquid petroleum and chemical products, organic compounds, and other corrosive materials and products.

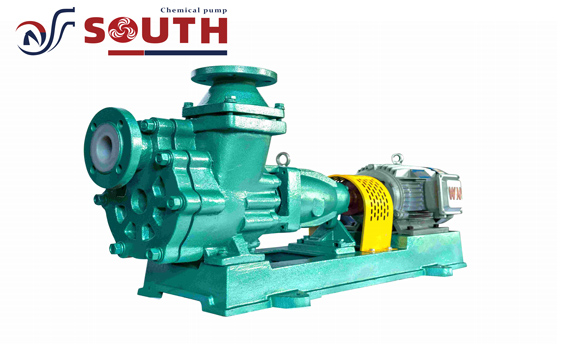

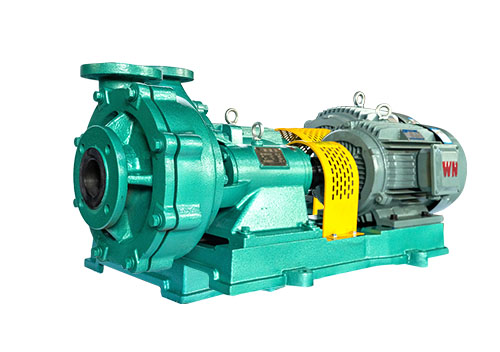

Chemical Process Pump

Pump cover gasket is made of polytetrafluoroethylene or metal winding, shaft adopts steel shaft design, pump shaft winding is small, and operation is stable. sealing chamber adopts a large cavity structure, medium fluidity is good, and isolation sleeve completely avoids the contact between the shaft and the medium.

Chemical Process Pump usage

Conveying various temperature and concentration of alkaline solution, various salt solution. suitable for the chemistry, petrochemical, refinery, paper, pulp, and sugar industries, as well as for media with special requirements.

Long Shaft Submerged Pump

Pump shafts choose reliable connected shaft form, submerged parts of pump shaft adopt sliding bearing supports, upper of liquids adopts angular contact ball bearing, method of lubrication are grease lubrication. It is designed two flushing models of self – flushing and outside flushing to lubrication and cooling sliding bear to make it can stable operation in long time.

Long Shaft Submerged Pump usage

Widely used in industrial wastewater pumping, surface treatment, sulfuric acid, sulfur liquid or other neutral or corrosive, clean or contain some particle and fiber content of the medium transmission process.

Corrosion Wear Resistant Slurry Pump

Slurry Pump is designed for conveying liquids contain corrosive and particles or crystallized mediums, impeller of is semi-opened type, it enhances the flow channel through ability, shaft seal is divided into K type sealing ring with outside cooling water system device and external bellows mechanical seal. It will have dual requirements of anti-corrosive and wear resistance.

Slurry Pump usage

Suitable for conveying solid content under 40% neutral or corrosive slurry, in desulfurization denitration , chemical fertilizer, salt and other industries have excellent performance.

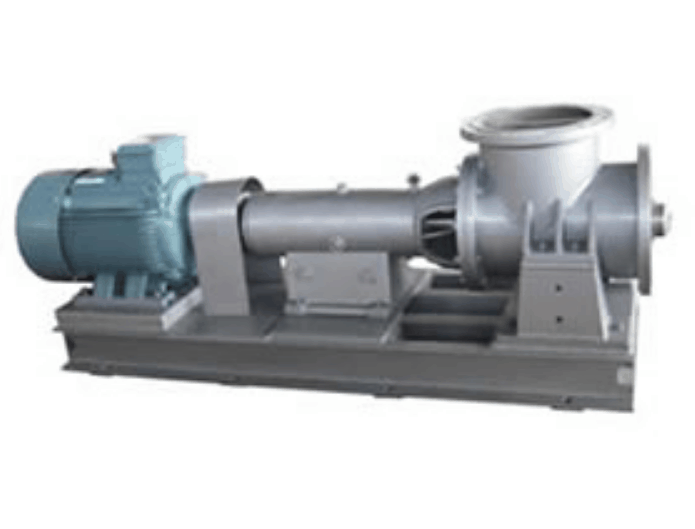

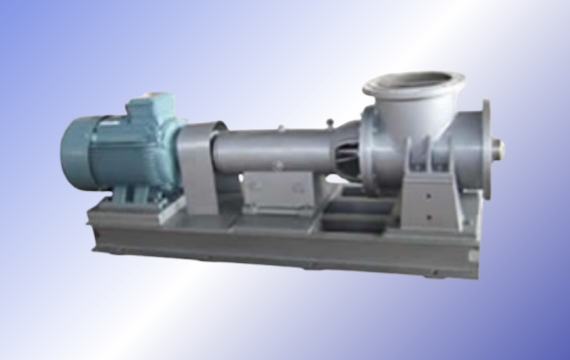

Chemical Axial Circulation Pump

Chemical axial circulation Pump is designed for cantilever structure, shaft seal is combination of dynamic seal and mechanical seal, it keeps pump without leakage when operated pump or stop running. the overflow liquids flow direction is horizontal direction (suction), vertical direction (exhaust) of pump. the materials of pump not only stainless steel, anti-corrosion wear resistant, but also can lining fluorine plastic, PE according to different working conditions and meet different clients choose.

Chemical Axial Circulation Pump Usage

Ammonium phosphate, phosphoric acid, vacuum salt, alumina, caustic soda, the forced circulation evaporator in light industry and other industries, can also be crystallizer circulating pump, and the reactor.

Which Fields Need Chemical Pumps

Biological medicine

Pharmaceutical transportation, circulation of injection water, etc.,

Petrochemical

Transportation of crude oil, petroleum products, chemical raw materials, chemical products, liquefied gas and other liquid media.

Power industry

Centrifugal pumps are used in circulating water systems, water supply systems, circulating cooling systems, etc.

Mining and metallurgical industries

Transportation of various corrosive liquids, high-temperature media, and materials such as slurry and slag slurry containing large particles and high concentrations. mines need to be drained by pumps, and pumps are also needed to supply water during mineral processing, smelting and rolling.

Port shipping

Including port water supply, ship refueling, ship drainage, marine mineral mining, etc.

Chemical industry

Centrifugal pumps are used in the chemical industry to transport liquids, stirred reactors, mixing tanks, etc., including fertilizer plants, synthetic resin plants, paint plants, pigment plants, etc.

Water treatment

Centrifugal pumps are often used in municipal water supply, drainage, water supply and drainage, sewage treatment and other fields, and are used to transport water from one place to another, including urban tap water, sewage treatment plants, industrial water, irrigation systems, etc.

Other applications

Such as urban water supply and drainage, water for steam locomotives, lubrication and cooling in machine tools, transporting bleach and dye in the textile industry, transporting pulp in the paper industry, and transporting milk and sugar in the food industry all require a large number of centrifugal pumps.

Pump Material Types

Fluorine plastic

company’s fluorine-butterfly pump technology on behalf of the domestic top level, Fluorine lined pump has extremely high corrosion resistance, high and low temperature resistance, electrical insulation performance, and low friction coefficient.

Pumps of this material include lining fluorine plastic chemical centrifugal pump, Fluorine plastic alloy centrifugal pump, Fluorine plastic lined-in self-priming pump.

Stainless steel

The corrosion resistance of stainless steel is slightly lower than that of fluorine plastic, but it has good heat resistance, excellent strength, hygienic properties and durability. It can resist neutral or corrosive liquids and salt solutions of various temperatures.

Pumps made of this material include stainless steel centrifugal pumps, which are more commonly used in the field of fine chemicals. In addition, long-axis submersible pumps also belong to this material.

UHMWPE

UHMWPE refers to ultra-high molecular polyethylene, which has high wear resistance, high impact strength and low friction coefficient. It is extremely chemically inert and can be used in highly corrosive or corrosive environments at moderate temperatures. Pumps made of this material include slurry pump.

Corrosion-resistant and wear-resistant alloys

Corrosion-resistant and wear-resistant alloys have the characteristics of corrosion resistance, wear resistance, high strength and strong toughness. they are widely used in aerospace, automobile, petroleum, medical and food fields. Pumps made of this material include chemical process pump and chemical circulation pump.

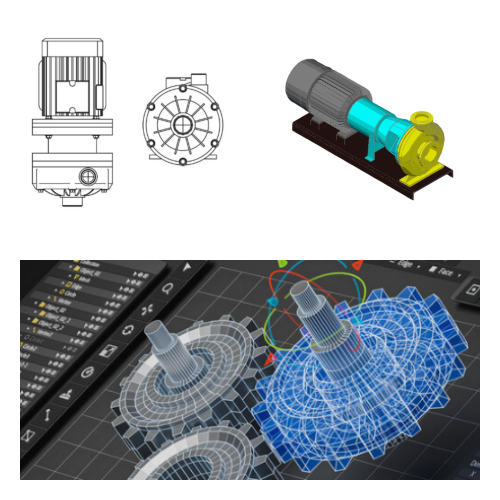

Production Details of Chemical Pumps Shows the Quality

Design

The product design adopts CAD-aided design system, especially the product’s hydraulic model design has incorporated advanced CFD technology to “visualize” the flow in the pump, thus providing a basis for improving the design and optimizing the performance of the pump.

Material selection

The raw materials needed by the company are all provided by well-known manufacturers and are equipped with batch chemical analysis reports. The company has also introduced a spectrum detection analyzer produced in Germany to ensure the authenticity and accuracy of the purchased raw materials.

Production

The company has more than 80 sets of various processing equipment, including 2 sets of automated robot finishing, 7 sets of modular machining centers, and more than 20 precision CNC lathes. All parts of the product are processed using intelligent CNC machinery.

Inspection

The company has introduced national-level pump product full performance testing facilities to ensure that each product shipped meets national standards and enterprise standards. The “three-inspection system” is implemented in product inspection: self-inspection and mutual inspection by workers, and special inspection by professionals, and occasional process inspections are carried out to further ensure the stability of product quality.

Centrifugal Pump Performance Reference Table

|

medium |

concentration≤% |

Temperature ≤25℃ |

Temperature ≤95℃ |

medium |

concentration≤% |

Temperature ≤25℃ |

Temperature ≤95℃ |

|

H2SO4 |

√ |

√ |

KOH |

50 |

√ |

√ |

|

|

HNO3 |

√ |

× |

NH2H2O |

√ |

× |

||

|

HCL |

√ |

√ |

Ba(OH)2 |

50 |

√ |

√ |

|

|

H3PO4 |

√ |

√ |

Mg(OH)2 |

√ |

√ |

||

|

HF* |

√ |

√ |

Ai(OH)3 |

√ |

√ |

||

|

HBr |

√ |

√ |

LiOH |

√ |

√ |

||

|

HI |

√ |

√ |

CiH2O |

√ |

√ |

||

|

Hydrogen cyanide |

√ |

√ |

Br2 |

√ |

√ |

||

|

H2SO3 |

√ |

√ |

Iodine solution12 |

√ |

√ |

||

|

NHO2 |

√ |

√ |

NH3 |

√ |

√ |

||

|

HCLO* |

√ |

√ |

CH3OH |

√ |

√ |

||

|

HCLO4 |

√ |

√ |

CH3CH2OH |

√ |

√ |

||

|

H2CrO4 |

80 |

√ |

√ |

C4H10O |

√ |

√ |

|

|

Aqua regia* |

√ |

√ |

HCHO |

√ |

√ |

||

|

CH3COOH |

√ |

√ |

CH3CHO |

√ |

√ |

||

|

HCOOH |

√ |

√ |

C4H8C12O |

√ |

√ |

||

|

CH4H8O2 |

√ |

√ |

C6H7N |

√ |

√ |

||

|

C5H10O2 |

√ |

√ |

CH3C1 |

√ |

√ |

||

|

C18H34O2 |

√ |

√ |

CH2C2 |

√ |

√ |

||

|

C6H5COOH |

√ |

√ |

C2H4Cl2 |

√ |

√ |

||

|

NaOH |

50 |

√ |

√ |

C2H4Cl4 |

√ |

√ |

|

|

√ is show have good corrosion resistance; × is show easy corrosive; * it indicates some of parts materials need be replaced; No Marked concentration of arbitrary symbols that can be. |

|||||||

trouble | Reason | Trouble shooting |

No liquids | Air in suction. | Refill liquids. |

Leakage of air in suction pipe. | Check suction pipeline. | |

Injected liquids is not enough in pump cavity. | Re-injected liquids in pump cavity. | |

Block up impurities in suction pipeline. | Clean up blocking impurities. | |

Reverse rotating. | Adjust rotating directory. | |

Suction height is too high. | Turn down installment height. | |

Flow rate insufficiency | Impeller damage. | Replaced new impeller. |

Rotating speed not enough. | Check up motor and electric wire. | |

Impurities blocked in pipeline. | Clean up impurities. | |

Overload horsepower | The proportion of the transmission medium is too large. | Reduce viscosity or increase perfusion pressure. |

The deviation between the pump axis and the motor axis is too large. | Adjust again. | |

Mechanical friction. | Check where friction and repair it. | |

Pump Head insufficiency | Transfer liquids contained air. | Refill the liquids and exhaust air in the medium. |

Impeller damage. | Replaced new impeller. | |

Rotation speed not enough. | Check up motor and electric wire. | |

The specific gravity is too high. | Reduce viscosity or increase the input pressure. | |

Pump set vibration | The deviation between the pump axis and the motor axis is too large. | Adjust again. |

Suction height is too large to produce | Turn down pump mounting height. | |

Mechanical friction existence. | Check the mechanical friction and repair it. | |

Sealing leakage | The snap ring gap is too large and the snap ring is loose. | Adjusting the snap ring screws. |

Suction height is too large to produce cavitation. | Turn down pump mounting height. | |

Dynamic and static mechanical seal wear and spring pressure is not enough. | Replace the components with friction. Adjust the spring. | |

Dynamic and static mechanical seal can’t match. | Adjusting dynamic and static seal. |

Use And Maintenance

Installation and the matters needing attention

1. Do a inspection of the pump and motor , make sure all the components are in good conditions and there is no sundries .

2. After installation , please turn the coupling and check whether it has collision and friction, if it can turn smoothly without break. Then finished installation.

3. There should be a filter in the inlet of the pumps. The filter surface of the area should be large than 3 or 4 times of the pipeline area.

4. The Pump with high head should install a cut off valve avoid the damage of water hummer when the pump stop working abruptly.

5. Make sure the installation height of the pumps conform to NPSH of the pump, consider with pipeline loss and transfer liquids temperature.

6. When the temperature of medium is too high , please choose cooling measure for mechanical seal to protect it distortion.

Pump Maintenance

1. Please fill transfer liquids into pump cavity before starting up, close outlet valve, connect the electric power.

2. Open Electric Power, check whether pump rotating direction is right or not .

3. Pump set test about 5-10 minute, then running operation if without abnormal.

4. When you want to stop this pump, please close outlet valve, then cut off power.

5. Do inspection of the pump and motor regularly, replace the components which are easy to be worn out.

6. If this pump is long time never running, you have to clean up pump cavity and cut off electric power.

7. It is forbidden Dry Running.

Related Product

Send Your Inquiry Today

How long is your warranty period?

One year.

How to install the pump correctly?

We have a professional team to guide and provide free teaching, and will also provide a set of installation instructions

How long does it take for your delivery?

Usually 7-15 days.

How do I get a quote?

Please provide the flow, head, power, purpose and quantity of the pumps you require so that we can provide you with an accurate quote.

What payment methods do you accept?

We accept payment by T/T, L/C.