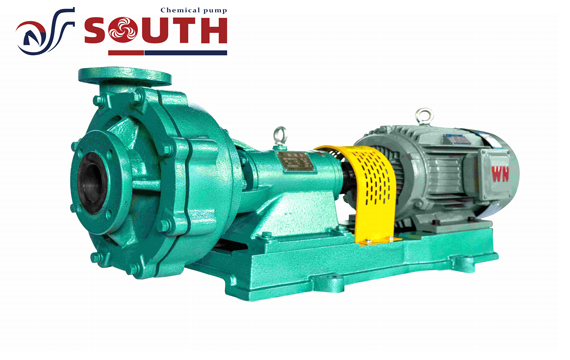

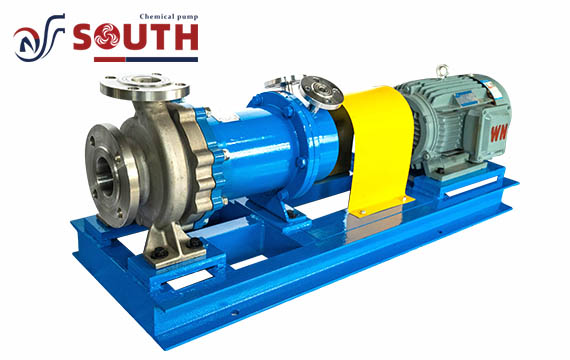

UHB-ZK corrosion wear resistant slurry pump has obvious advantages when conveying a slurry with a solid content of no more than 40%, in the desulfurization cycle, acid phosphate fertilizer industry, fine chemical industry have a very good performance.

Corrosion wear resistant slurry pump is made of lined UHMW-PE, which has a high reputation for wear resistance, compared to stainless steel , its wear resistance is 6-7 times higher.

Corrosion wear resistant slurry pump fall into the category of single stage single suction pump, pump diameter is 25-350mm, flow capacity range is 2m³/h-400m³/h, pump head range is 15m-80m.

There are many other pump types in UHB-ZK series, and corrosion wear resistant slurry pumps with different parameters can be selected according to the specific situation.

Designed instruction of UHB-ZK series slurry pump

The UHB-ZK Series Slurry Pump is a single-stage, single-suction centrifugal pump specifically engineered for conveying liquids that contain corrosive substances, particles, or crystallized mediums. The impeller features a semi-open design, enhancing the pump’s ability to handle fluids with varying viscosities and particulate content. The shaft seal is available in two configurations: a K-Type sealing ring with an external cooling water system or an external bellows mechanical seal. This design effectively meets the dual requirements of corrosion resistance and wear resistance, making it suitable for both clean liquids and slurry transfers.

The wear resistance of this pump surpasses that of conventional materials like carbon steel and stainless steel by 6 to 7 times. Additionally, it boasts self-lubricating properties with a low friction coefficient, making it an ideal choice as an alternative to high-wear-resistant alloy materials.

Advantages of corrosion wear resistant slurry pump

Exceptional Corrosion Resistance: the pump is designed to withstand harsh and corrosive environments, ensuring reliable performance even when handling aggressive slurries. This extends its service life and reduces maintenance costs.

Leak-Proof Design: the advanced sealing system ensures that the pump operates without leaks, protecting the environment and equipment from potential damage caused by fluid spills.

Superior Wear Resistance: the materials used in the pump exceed the wear resistance of traditional materials, significantly prolonging its service life and reducing maintenance costs.

Efficient Fluid Handling: the semi-open design of the impeller enhances the pump’s ability to handle fluids with varying viscosities and particulate content, ensuring efficient operation across various operating conditions.

Durability and Reliability: the combination of corrosion resistance, wear resistance, and leak-proof design makes the UHB-ZK Series Slurry Pump a durable and reliable solution for critical industrial applications.

Low Maintenance: the pump’s design and materials contribute to its low maintenance requirements, reducing downtime and overall operating costs.

Application areas of corrosion wear resistant slurry pump

The UHB-ZK Series Slurry Pump is highly suitable for conveying slurries with up to 40% solid content, whether neutral or corrosive. It demonstrates excellent performance in industries such as desulfurization and denitrification, chemical fertilizers, and salt processing. This pump is widely used in various applications, including desulfurization cycles, non-ferrous metal smelting, the paper industry, acid phosphate fertilizer production, petrochemical processes, fine chemicals, electric power generation, metallurgy, water treatment and discharge, and mining operations.

Corrosion wear resistant slurry pump performance parameters of the table

| Model No | Flow Capacity

(m3/h) |

Pump Head

(m) |

Motor Power

(KW) |

Rotating Speed

(r/min) |

Efficiency

(%) |

Shaft power

(KW) |

NPSH(m) | Diameter(mm) | |

| Inlet | outlet | ||||||||

| 40UHB-ZK-10-20 | 5 | 23 | 3 | 2900 | 20 | 1.6 | 3 | 40 | 32 |

| 10 | 20 | 25 | 2.2 | ||||||

| 15 | 18 | 28 | 2.6 | ||||||

| 40UHB-ZK-10-30 | 5 | 32 | 4 | 2900 | 30 | 1.5 | 3 | ||

| 10 | 30 | 36 | 2.3 | ||||||

| 15 | 26 | 30 | 3.5 | ||||||

| 50UHB-ZK-20-20 | 15 | 23 | 4 | 2900 | 30 | 3.1 | 3 | 50 | 40 |

| 20 | 20 | 32 | 3.4 | ||||||

| 25 | 18 | 35 | 3.5 | ||||||

| 50UHB-ZK-20-30 | 15 | 32 | 5.5 | 2900 | 33 | 4.0 | 3 | ||

| 20 | 30 | 37 | 4.4 | ||||||

| 25 | 28 | 40 | 4.8 | ||||||

| 65UHB-ZK-30-20 | 20 | 25 | 5.5 | 2900 | 35 | 3.9 | 3.5 | 65 | 50 |

| 30 | 20 | 42 | 4.1 | ||||||

| 35 | 18 | 37 | 4.4 | ||||||

| 65UHB-ZK-30-30 | 20 | 35 | 7.5 | 2900 | 38 | 5.0 | 3.5 | ||

| 30 | 30 | 42 | 5.8 | ||||||

| 40 | 26 | 45 | 6.3 | ||||||

| 65UHB-ZK-30-50 | 20 | 55 | 15 | 2900 | 30 | 10.0 | 3.5 | ||

| 30 | 50 | 35 | 11.7 | ||||||

| 40 | 45 | 38 | 12.9 | ||||||

|

65UHB-ZK-25-70 |

18 | 78 |

18.5 |

2900 |

35 | 10.9 | 18.5 | 65 | 50 |

| 25 | 75 | 43 | 11.9 | ||||||

| 35 | 70 | 50 | 13.4 | ||||||

|

80UHB-ZK-50-20 |

40 | 23 |

11 |

2900 |

33 | 7.6 | 11 | 80 | 65 |

| 50 | 20 | 35 | 7.8 | ||||||

| 60 | 18 | 30 | 9.8 | ||||||

|

80UHB-ZK-50-30 |

30 | 33 |

15 |

2900 |

35 | 7.7 | 15 | ||

| 50 | 30 | 42 | 9.7 | ||||||

| 60 | 26 | 36 | 11.8 | ||||||

|

80UHB-ZK-50-50 |

30 | 33 |

18.5 |

2900 |

35 | 7.7 | 18.5 | ||

| 50 | 50 | 42 | 16.2 | ||||||

| 60 | 40 | 36 | 18.2 | ||||||

|

80UHB-ZK-50-80 |

30 | 83 |

30 |

2900 |

36 | 18.9 | 30 | ||

| 50 | 80 | 46 | 23.3 | ||||||

| 60 | 70 | 42 | 27.3 | ||||||

|

100UHB-ZK-60-35 |

50 | 37 |

18.5 |

2900 |

45 | 11.2 | 22 | 100 | 80 |

| 60 | 35 | 47 | 12.2 | ||||||

| 70 | 32 | 49 | 12.5 | ||||||

|

100UHB-ZK-65-50 |

50 | 55 |

22 |

2900 |

45 | 16.7 | 18.5 | ||

| 60 | 50 | 47 | 17.4 | ||||||

| 70 | 45 | 49 | 17.5 | ||||||

|

100UHB-ZK-100-20 |

80 | 23 |

18.5 |

2900 |

32 | 15.7 | 22 | ||

| 100 | 20 | 32 | 17.0 | ||||||

| 120 | 15 | 28 | 17.5 | ||||||

|

100UHB-ZK-100-30 |

80 | 35 |

22 |

2900 |

43 | 17.7 | 30 | ||

| 100 | 30 | 44 | 18.6 | ||||||

| 140 | 23 | 46 | 19.1 | ||||||

|

100UHB-ZK-100-40 |

80 | 45 |

30 |

2900 |

44 | 22.3 | 45 | ||

| 100 | 40 | 42 | 26.0 | ||||||

| 137 | 24 | 31 | 28.9 | ||||||

| 100UHB-ZK-100-50 | 80 | 58 |

45 |

2900 |

40 | 31.6 | 45 | ||

| 100 | 50 | 42 | 32.4 | ||||||

| 120 | 42 | 36 | 38.2 | ||||||

|

300UHB-ZK-1000-50 |

850 | 55 |

250 |

1450 |

59 | 215.9 |

7 |

300 | 250 |

| 1000 | 50 | 60 | 227.1 | ||||||

| 1100 | 48 | 62 | 232.1 | ||||||

|

300UHB-ZK-1200-20 |

1000 | 23 |

160 |

1450 |

63 | 99.5 |

6.5 |

||

| 1200 | 20 | 63 | 103.8 | ||||||

| 1400 | 16 | 43 | 142.0 | ||||||

|

300UHB-ZK-1200-30 |

1000 | 32 |

185 |

1450 |

58 | 150.3 |

6.5 |

||

| 1200 | 30 | 60 | 163.5 | ||||||

| 1400 | 28 | 61 | 175.1 | ||||||

|

350UHB-ZK-1400-20 |

1100 | 23 |

132 |

1450 |

70 | 98.5 |

6.5 |

250 | 300 |

| 1400 | 20 | 71 | 107.5 | ||||||

| 1500 | 16 | 60 | 109.0 | ||||||

|

350UHB-ZK-1400-32 |

1250 | 35 |

250 |

1450 |

67 | 177.9 |

7 |

||

| 1400 | 32 | 68 | 179.5 | ||||||

| 1600 | 27 | 56 | 210.2 | ||||||

|

350UHB-ZK-1600-20 |

1400 | 22 |

200 |

1450 |

53 | 158.4 |

7 |

||

| 1600 | 20 | 55 | 158.6 | ||||||

| 1800 | 18 | 48 | 183.9 | ||||||

|

350UHB-ZK-1600-32 |

1400 | 35 |

250 |

1450 |

61 | 218.9 |

6.5 |

||

| 1600 | 32 | 62 | 225.0 | ||||||

| 1800 | 27 | 58 | 228.2 | ||||||