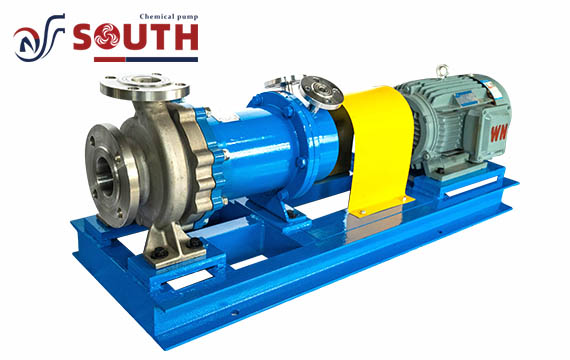

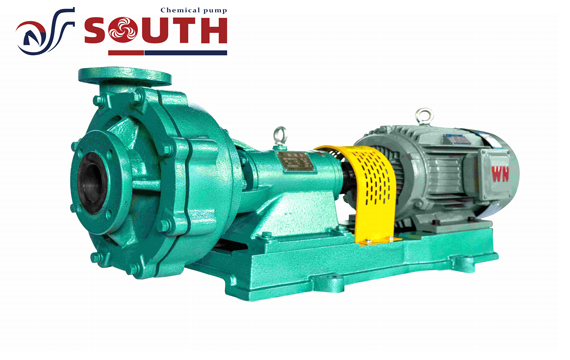

Stainless steel centrifugal pump is made of stainless steel, and stainless steel in anti-corrosion and wear resistance also has a great authority. It can transport some media containing solid particles, and various concentrations of acid and base. the pump bears a temperature range of -20℃-165℃.

Because stainless steel does not rust and smooth surface, not easy to hide dirt, so quite popular in some food industry and industry with high health requirements, in the urban water supply project, stainless steel centrifugal pump is also essential.

Of course, pumps are used far more applications than that. some new energy, new materials, paper, electroplating industry, stainless steel pump is simply a standard chemical pump.

Most importantly, multiple parts of this pump are selectable such as specifications bracket, seals, impeller and so on.

Designed instruction of stainless steel centrifugal pump

The ZH Series chemical process pump is a cutting-edge product designed to supersede the IH Series. It maintains identical performance parameters and installation dimensions as the IH Series, ensuring seamless integration into existing systems. This pump adheres to the GB/T5662 Standard, which defines the marks, performance, and specifications for axial direction end-suction centrifugal pumps (16 bar). It offers high interchangeability with common spare parts, making maintenance and part replacement efficient.

The ZH Series features five bracket specifications, covering the full range of pump sizes within the series. Depending on the client’s requirements, it can be equipped with either gland packing or mechanical seals. The mechanical seal options include single-face, double-face, balanced, or unbalanced designs. Additionally, the impeller can be configured as open-type or semi-open type, allowing the pump to handle liquids containing certain fibers or particles. This pump is a standard chemical centrifugal pump ideal for use in various fine chemical industries.

Application areas of stainless steel centrifugal pump

This centrifugal pump is suitable for conveying clean liquids or those containing solid particles and fibers, as well as low-temperature or high-temperature, neutral, or corrosive media. It is widely used for handling alkaline solutions of various temperatures and concentrations, various salt solutions, different liquid petroleum and chemical products, organic compounds, and other corrosive materials and products. it is widely used in the fields of biopharmaceuticals, petrochemicals, power generation, metallurgy, and aerospace.

Advantages of stainless steel Centrifugal Pumps

Flexible Sealing Options: Offers customizable sealing choices, including gland packing and various mechanical seals (single-face, double-face, balanced, or unbalanced), to meet diverse application needs.

Versatile Impeller Design: Features an adaptable impeller configuration, available in open-type or semi-open type, enabling the pump to efficiently handle liquids with fibers or particles.

Broad Media Compatibility: Capable of conveying a wide range of fluids, including clean or contaminated, low-temperature or high-temperature, neutral or corrosive liquids.

Wide Range of Applications: Suitable for various industries such as biopharmaceuticals, petrochemicals, power generation, metallurgy, and aerospace, demonstrating its versatility and adaptability.

Stainless steel centrifugal pump performance parameters of the table

| Model No | Flow Capacity

(m3/h) |

Pump Head

(m) |

Motor Power

(KW) |

Rotating Speed

(r/min) |

Efficiency

(%) |

Shaft power

(KW) |

NPSH(m) | Diameter(mm) | |

| Inlet | outlet | ||||||||

| NH40-25-125 | 4 | 22 | 1.5 | 2900 | 40 | 0.60 | 2 | 40 | 20 |

| 6 | 20 | 0.82 | |||||||

| 8 | 18.5 | 1.01 | |||||||

| 2 | 5.5 | 0.55 | 1450 | 34 | 0.09 | 2 | |||

| 3 | 5 | 0.12 | |||||||

| 4 | 4.5 | 0.14 | |||||||

| NH40-25-160 | 4 | 34 | 2.2 | 2900 | 33 | 1.12 | 2 | 40 | 25 |

| 6 | 32 | 1.59 | |||||||

| 8 | 28 | 1.85 | |||||||

| 2 | 9 | 0.55 | 1450 | 27 | 0.18 | 2 | |||

| 3 | 8 | 0.24 | |||||||

| 4 | 7 | 0.28 | |||||||

| NH40-25-200 | 4 | 52 | 4 | 2900 | 26 | 2.18 | 2 | 40 | 25 |

| 6 | 50 | 3.14 | |||||||

| 8 | 48 | 4.02 | |||||||

| 2 | 13.5 | 0.75 | 1450 | 20 | 0.37 | 2 | |||

| 3 | 12.5 | 0.51 | |||||||

| 4 | 12 | 0.65 | |||||||

| NH65-50-160 | 15 | 33 | 5.5 | 2900 | 56 | 2.41 | 3.5 | 65 | 50 |

| 25 | 32 | 3.89 | |||||||

| 30 | 28 | 4.09 | |||||||

| 7.5 | 8.6 | 1.1 | 1450 | 50 | 0.35 | 3.5 | |||

| 12.5 | 8 | 0.55 | |||||||

| 15 | 7 | 0.57 | |||||||

| NH65-40-200 | 15 | 52 | 11 | 2900 | 52 | 4.09 | 3.5 | 65 | 40 |

| 25 | 50 | 6.55 | |||||||

| 30 | 48 | 7.55 | |||||||

| 7.5 | 13 | 1.5 | 1450 | 46 | 0.58 | 3.5 | |||

| 12.5 | 12.5 | 0.93 | |||||||

| 15 | 12 | 1.07 | |||||||

| NH65-40-250 | 15 | 82 | 18.5 | 2900 | 42 | 7.98 | 3.5 | 65 | 40 |

| 25 | 80 | 12.98 | |||||||

| 30 | 78 | 15.18 | |||||||

| 7.5 | 20.5 | 3 | 1450 | 43 | 0.97 | 3.5 | |||

| 12.5 | 20 | 1.58 | |||||||

| 15 | 19.5 | 1.85 | |||||||

| NH65-40-315 | 15 | 127 | 30 | 2900 | 42 | 12.36 | 3.5 | 65 | 40 |

| 25 | 125 | 20.28 | |||||||

| 30 | 123 | 23.94 | |||||||

| 7.5 | 33 | 5.5 | 1450 | 37 | 1.82 | 3.5 | |||

| 12.5 | 32 | 2.95 | |||||||

| 15 | 30 | 3.31 | |||||||

| NH80-65-125 | 40 | 22 | 5.5 | 2900 | 65 | 3.69 | 4 | 80 | 65 |

| 50 | 20 | 4.19 | |||||||

| 60 | 18.5 | 4.65 | |||||||

| 20 | 5.5 | 1.1 | 1450 | 58 | 0.52 | 4 | |||

| 25 | 5 | 0.59 | |||||||

| 30 | 4.6 | 0.65 | |||||||

| NH125-100-250 | 150 | 82 | 90 | 2900 | 68 | 49.29 | 5 | 125

|

100

|

| 200 | 80 | 64.12 | |||||||

| 240 | 73 | 70.21 | |||||||

| 75 | 20.5 | 15 | 1450 | 62 | 6.76 | 5 | |||

| 100 | 20 | 8.79 | |||||||

| 120 | 19.5 | 10.28 | |||||||

| NH125-100-315 | 75 | 33 | 15 | 1450 | 72 | 9.37 | 5 | 125 | 100 |

| 100 | 32 | 12.11 | |||||||

| 120 | 30 | 13.63 | |||||||

| NH125-100-400 | 75 | 52 | 37 | 1450 | 55 | 19.32 | 5 | 125 | 100 |

| 100 | 50 | 24.77 | |||||||

| 120 | 48 | 28.54 | |||||||

| NH150-125-250 | 150 | 20.5 | 22 | 1450 | 68 | 12.32 | 6 | 150 | 125 |

| 200 | 20 | 16.03 | |||||||

| 240 | 19.5 | 18.75 | |||||||

| NH150-125-315 | 150 | 33 | 30 | 1450 | 75 | 17.99 | 6 | 150 | 125 |

| 200 | 32 | 23.25 | |||||||

| 240 | 30 | 26.16 | |||||||

| NH150-125-400 | 150 | 52 | 55 | 1450 | 72 | 29.52 | 6 | 150 | 125 |

| 200 | 50 | 37.85 | |||||||

| 240 | 48 | 43.60 | |||||||

| NH200-150-250 | 250 | 20.5 | 37 | 1450 | 74 | 18.87 | 7 | 200 | 150 |

| 400 | 20 | 29.46 | |||||||

| 460 | 19.5 | 33.03 | |||||||

| NH200-150-315 | 250 | 33 | 55 | 1450 | 79 | 28.46 | 7 | 200 | 150 |

| 400 | 32 | 44.15 | |||||||

| 460 | 30 | 47.60 | |||||||

| NH200-150-400 | 250 | 52 | 90 | 1450 | 78 | 45.42 | 7 | 200 | 150 |

| 400 | 50 | 69.87 | |||||||

| 460 | 48 | 77.14 | |||||||