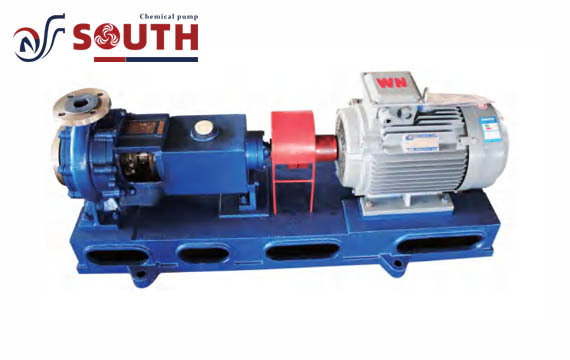

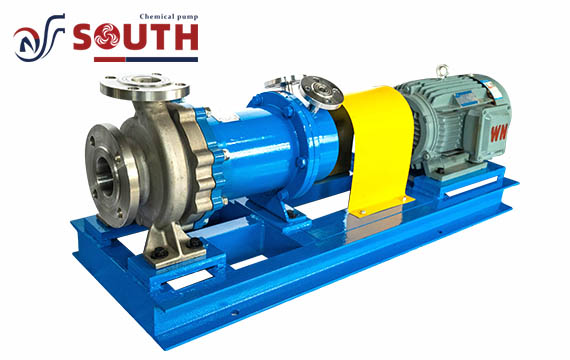

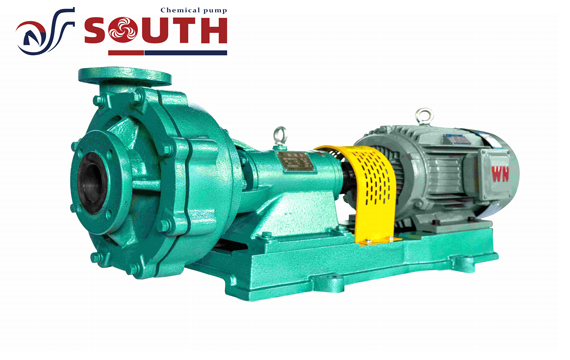

NZ series chemical process pump is made of carbon steel, stainless steel, corrosion-resistant and wear-resistant metal. pump’s corruption resistance, wear resistance and high temperature resistance are better than other alloy material pumps, and it can withstand great pressure and tension.

The sealing cavity design of the chemical process pump is relatively large, convenient flow of medium, and heat dissipation is relatively fast. like some electrolytes, liquid oil, organic compounds, and other toxic and harmful substances, with a concentrated medium, the chemical process pumps can be delivered.

The performance of chemical process pumps is also excellent, its flow capacity range is 3m³/h-2000m³/h, pump head range is 12.5m-160m, such high flow and head makes it very popular in major factories, like metallurgy, textile printing and dyeing, space fight field and others.

Designed instruction of NZ series chemical process pump

NZ Industrial Chemical Pump is a horizontal, single-stage cantilever-supported, single-suction centrifugal pump. Product performance design adheres to International Standards including API610 for pump impeller construction, which is precision cast for enhanced durability. The impeller features a Balanced Axial Force design, and the pump casing incorporates a large cavity structure compliant with API682 requirements. The fluid flow is optimized for rapid movement and efficient heat dissipation. Sealing options include single end face, double end face, or series connection types. The mechanical seal can be container or non-container based, tailored to application needs.

Bearings utilize a standard thin oil lubrication system, ensuring effective cooling and prolonged operational life. The pump shaft is constructed with a rigid design to minimize deflection, ensuring smooth and stable operation. Full isolation shaft sleeves are employed to prevent the axis from contacting the pumped medium, thereby significantly extending pump longevity. the wear-resistant rings positioned between the pump body and impeller reduce direct friction, lowering overall running costs. Coupling connection structures are adopted for ease of maintenance, allowing repairs without the need to dismantle pipelines.

Advantages of chemical process Pumps

Wide Fluid Handling Range: Capable of transporting various liquids, including those with solid particles and fibrous content, across a broad temperature spectrum from low to high, and suitable for both neutral and corrosive liquids.

Excellent Corrosion Resistance: Efficiently manages corrosive media, including various concentrations of alkaline solutions, salt solutions, liquid petroleum, chemical products, and organic compounds, making it ideal for harsh environments in the chemical and petroleum industries.

Efficient Heat Dissipation and Fluid Flow: Optimized fluid dynamics ensure rapid movement and effective heat dissipation, contributing to higher operational efficiency and stability.

Versatile Sealing Options: Offers multiple sealing methods, including single end face, double end face, and series connection types, with container or non-container-based mechanical seals, catering to diverse operational requirements.

Durability and Wear Resistance: Features a Balanced Axial Force design and wear-resistant rings, which reduce direct friction, extend pump lifespan, and lower operational costs.

Application areas of chemical process pump

Designed for the transport of clean or particulate-laden liquids, including those with fibrous content. Capable of handling fluids across a broad temperature range, from low to high, and suitable for both neutral and corrosive liquids. It effectively manages varying concentrations of alkaline solutions, diverse salt solutions, as well as a wide array of liquid petroleum products, chemical compounds, organic substances, and other corrosive materials and products.

In the chemical and petrochemical industries, process pumps handle a wide range of corrosive chemicals, high-viscosity fluids, and abrasive mixtures. Pumps are essential for the transfer of acids, alkalis, and other reactive substances, as well as for maintaining fluid circulation during chemical reactions, separation processes, and in the storage and distribution of raw materials and finished products.

Chemical process pump performance parameters of the table

| Model No | Flow Capacity

(m3/h) |

Pump Head

(m) |

NPSH(m) | Efficiency

(%) |

Shaft power

(KW) |

Motor Power

(KW) |

Rotating Speed

(r/min) |

Diameter(mm) | |

| Inlet | outlet | ||||||||

|

NZ32-160 |

7.5 | 34.5 | 2 |

62 |

1.14 |

4 |

2900 |

50 |

32 |

| 12.5 | 32 | 2 | 1.76 | ||||||

| 15 | 30 | 2.5 | 1.98 | ||||||

| 3.75 | 8.6 | 2 |

49 |

0.18 |

1.1 |

1450 |

|||

| 6.3 | 8 | 2 | 0.28 | ||||||

| 7.5 | 7.5 | 2.5 | 0.31 | ||||||

|

NZ32-200 |

7.5 | 51.8 | 2 |

48 |

2.21 |

7.5 |

2900 |

50 |

32 |

| 12.5 | 50 | 2 | 3.55 | ||||||

| 15 | 48 | 2.5 | 4.09 | ||||||

| 3.75 | 12.9 | 2 |

37 |

0.36 |

1.5 |

1450 |

|||

| 6.3 | 12.5 | 2 | 0.58 | ||||||

| 7.5 | 12 | 2.5 | 0.66 | ||||||

|

NZ32-250 |

7.5 | 82 | 2 |

36 |

4.66 |

15 |

2900 |

50 |

32 |

| 12.5 | 80 | 2 | 7.57 | ||||||

| 15 | 78.5 | 2.5 | 8.91 | ||||||

| 3.75 | 20.5 | 2 |

30 |

0.70 |

2.2 |

1450 |

|||

| 6.3 | 20 | 2 | 1.14 | ||||||

| 7.5 | 16.2 | 2.5 | 1.10 | ||||||

| NZ50-200 | 30 | 55.2 | 2 | 62 | 7.28 | 18.5 | 2900 | 80 | 50 |

| 50 | 50 | 2.5 | 10.99 | ||||||

| 60 | 45.2 | 3.2 | 11.92 | ||||||

| 15 | 13.5 | 2 | 70 | 0.79 | 2.2 | 1450 | |||

| 25 | 12.5 | 2 | 1.22 | ||||||

| 30 | 11.5 | 2.5 | 1.34 | ||||||

| NZ50-250 | 30 | 84 | 2.5 | 54 | 12.72 | 37 | 2900 | 80 | 50 |

| 50 | 80 | 2.5 | 20.19 | ||||||

| 60 | 75 | 2.5 | 22.71 | ||||||

| 15 | 21 | 2 | 59 | 1.45 | 4 | 1450 | |||

| 25 | 20 | 2 | 2.31 | ||||||

| 30 | 18.8 | 2.5 | 2.60 | ||||||

| NZ50-315 | 30 | 128 | 2.5 | 40 | 26.16 | 75 | 2900 | 80 | 50 |

| 50 | 125 | 2.5 | 42.58 | ||||||

| 60 | 123 | 3 | 50.28 | ||||||

| 15 | 32.5 | 2 | 48 | 2.77 | 7.5 | 1450 | |||

| 25 | 32 | 2.5 | 4.54 | ||||||

| 30 | 31.5 | 3 | 5.36 | ||||||

| NZ65-160 | 60 | 37 | 3.8 | 54 | 11.20 | 22 | 2900 | 100 | 65 |

| 100 | 32 | 4.3 | 16.15 | ||||||

| 120 | 28 | 5 | 16.96 | ||||||

| 30 | 9.25 | 3 | 68 | 1.11 | 2.2 | 1450 | |||

| 50 | 8 | 3.4 | 1.60 | ||||||

| 60 | 7 | 3.7 | 1.68 | ||||||

| NZ65-200 | 60 | 56 | 3.4 | 63 | 14.53 | 37 | 2900 | 100 | 65 |

| 100 | 50 | 3.9 | 21.63 | ||||||

| 120 | 44 | 5.2 | 22.84 | ||||||

| 30 | 14 | 2.5 | 63 | 1.82 | 4 | 1450 | |||

| 50 | 12.5 | 2.5 | 2.70 | ||||||

| 60 | 11 | 3 | 2.85 | ||||||

| NZ200-500 | 450 | 40 | 4.5 | 81.5 | 60.18 | 185 | 1450 | 250 | 200 |

| 550 | 55 | 4.8 | 101.14 | ||||||

| 650 | 65 | 5 | 141.27 | ||||||

| NZ250-315 | 800 | 16 | 4.5 | 56 | 62.29 | 132 | 1450 | 300 | 250 |

| 900 | 20 | 5 | 87.59 | ||||||

| 950 | 22 | 5.5 | 101.70 | ||||||

| NZ250-400 | 800 | 24 | 4.9 | 83 | 63.04 | 185 | 1450 | 300 | 250 |

| 900 | 38 | 5 | 112.28 | ||||||

| 1000 | 44 | 5.5 | 144.46 | ||||||

| NZ250-500 | 850 | 45 | 5.5 | 85 | 122.63 | 355 | 1450 | 300 | 250 |

| 1000 | 55 | 5.5 | 176.32 | ||||||

| 1200 | 80 | 6 | 307.76 | ||||||

| NZ300-400 | 1300 | 20 | 5.5 | 87 | 81.44 | 220 | 1450 | 350 | 300 |

| 1400 | 30 | 5.5 | 131.55 | ||||||

| 1500 | 40 | 6 | 187.93 | ||||||

| NZ300-500 | 1100 | 40 | 5.5 | 83.5 | 143.59 | 315 | 1450 | 350 | 300 |

| 1300 | 50 | 5.5 | 212.13 | ||||||

| 1500 | 60 | 6 | 293.71 | ||||||