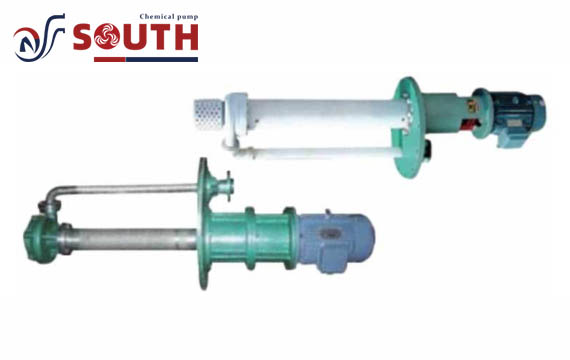

NFY FYS long shaft submerged pump is a pump that works underwater. of course, it is not limited to underwater. like sulfuric acid, sulfur liquid and other concentrated corrosive media, long shaft submersible pumps can treat.

The submersible pump material is mainly composed of stainless steel, ultra-polymer polyethylene, and corrosion resistant fluorine plastic; therefore, its corrosion resistance is very reliable.

Long shaft submerged pump can dive into the liquid up to about 7 meters, such as wastewater pumping in the industry, corrosive, granular medium transport in the petrochemical industry, are very suitable.

The design structure of long shaft submerged pump is very reasonable, specially designed balance cavity can effectively reduce the pump body pressure.

According to the specific situation, you can choose different ways to lubricate and cool sliding bearing, not only convenient operation, but also greatly extend the life of submerged pump.

Designed instruction of long shaft submerged pump

NFY/FYS Long Shaft Submerged Pump is a single-stage, single-suction vertical centrifugal pump. The design conforms to API610 VS4 Standard. The pump shaft utilizes a reliable connected shaft form, allowing the pump body to be submerged to depths of up to 7 meters. The submerged parts of the shaft are supported by sliding bearings, eliminating the need for shaft sealing. The upper liquid section incorporates angular contact ball bearings, with Grease Lubrication as the chosen lubrication method.

This pump features specially designed axial adjustment mechanisms that enable fine-tuning of the clearance between the impeller back-blade and the pump cover, ensuring balanced axial force. The unique balanced cavity structure helps relieve pressure, ensuring stable operation over time. It offers two flushing models—self-flushing and outside flushing—to lubricate and cool the sliding bearings, adaptable to different liquid temperatures and particle content. The sliding bearings are equipped with gland packing to prevent impurities from entering, reducing bearing wear and prolonging the pump’s working life.

Application areas of long shaft submerged pump

The NFY/FYS Long Shaft Submerged Pump is widely utilized across various industries for the efficient handling of a diverse range of liquids. It is particularly effective in the pumping of industrial wastewater, surface treatment processes, and the transportation of sulfuric acid, sulfur liquid, or other neutral or corrosive media. This pump is capable of transferring both clean liquids and those containing particles and fibrous content.

Its versatility makes it an essential component in fields such as biological medicine, petrochemical, mining, metallurgy, textile printing and dyeing, electricity, food processing, papermaking, electroplating, sewage treatment, and flue gas treatment. Additionally, it is increasingly being adopted in emerging sectors like new energy and new materials industries, where its robust design and reliable performance are highly valued.

Advantages of Centrifugal of long shaft submerged pump

Versatility in Media Handling: Capable of efficiently pumping a wide range of liquids, including industrial wastewater, sulfuric acid, sulfur liquids, and other neutral or corrosive media, as well as fluids containing particles and fibers.

Broad Industrial Application: Widely applicable across numerous industries, including biological medicine, petrochemical, mining, metallurgy, and more, making it a versatile solution for various industrial processes.

Reliable Submersion Capability: Designed for deep submersion, up to 7 meters, with robust sliding bearings and a reliable shaft structure, ensuring stable and continuous operation in demanding environments.

Enhanced Durability and Protection: Equipped with advanced lubrication and gland packing systems, which prevent impurities from entering the bearings, reduce wear, and prolong the pump’s operational life.

Adaptability to New Technologies: Increasingly adopted in emerging sectors such as new energy and new materials, demonstrating its adaptability to modern industrial challenges and innovations.

Long shaft submerged pump performance parameters of the table

| Model No | Flow Capacity

(m3/h) |

Pump Head

(m) |

Efficiency

(%) |

Shaft power

(KW) |

Motor Power

(KW) |

Rotating Speed

(r/min) |

Submerged depth (mm) | Diameter(mm) | |

| Inlet | outlet | ||||||||

| FYS25-25 | 1.5 | 27 | 16 | 0.69 | 2.2 | 2900 | 500-3000 | 25 | 20 |

| 2.5 | 25 | 18 | 0.95 | ||||||

| 3.5 | 20 | 17 | 1.12 | ||||||

| FYS32-20 | 3.5 | 22 | 27 | 0.78 | 1.5 | 2900 | 500-3000 | 32 | 23 |

| 5.5 | 20 | 25 | 1.20 | ||||||

| 7.5 | 16 | 23 | 1.42 | ||||||

| FYS40-20 | 5 | 22 | 35 | 0.86 | 2.2 | 2900

|

500-3000 | 40 | 32 |

| 7.5 | 20 | 39 | 1.05 | ||||||

| 10 | 16 | 36 | 1.21 | ||||||

| FYS50-25 | 10 | 28 | 36 | 2.12 | 4 | 2900 | 500-3000 | 50 | 40 |

| 12.5 | 25 | 37 | 2.30 | ||||||

| 18 | 16 | 32 | 2.45 | ||||||

| FYS50-50 | 7.5 | 52 | 32 | 3.32 | 7.5 | 2900 | 500-3000 | 32 | |

| 12.5 | 50 | 33 | 5.16 | ||||||

| 15 | 48 | 35 | 5.61 | ||||||

| FYS65-20 | 15 | 21.5 | 43 | 2.04 | 5.5 | 2900 | 500-3000 | 65 | 50 |

| 25 | 20 | 58 | 2.35 | ||||||

| 30 | 18.5 | 59 | 2.56 | ||||||

| FYS65-32 | 15 | 34 | 42 | 3.31 | 7.5 | 2900 | 500-3000 | 50 | |

| 25 | 32 | 55 | 3.96 | ||||||

| 30 | 28 | 57 | 4.02 | ||||||

| FYS65-50 | 15 | 53 | 39 | 5.55 | 11 | 2900 | 500-3000 | 40 | |

| 25 | 50 | 50 | 6.81 | ||||||

| 30 | 46 | 51 | 7.37 | ||||||

| FYS80-20 | 30 | 23 | 56 | 3.36 | 7.5 | 2900 | 500-3000 | 80 | 65 |

| 50 | 20 | 65 | 4.19 | ||||||

| 60 | 17 | 53 | 5.24 | ||||||

| FYS80-32 | 30 | 36 | 54 | 5.45 | 11 | 2900 | 500-3000 | 65 | |

| 50 | 32 | 63 | 6.92 | ||||||

| 60 | 28 | 53 | 8.64 | ||||||

| FYS80-50 | 30 | 55 | 55 | 8.18 | 18.5 | 2900 | 500-3000 | 80 | 50 |

| 50 | 50 | 50 | 13.63 | ||||||

| 60 | 45 | 45 | 16.35 | ||||||

| FYS100-20 | 60 | 24 | 60 | 6.54 |

15 |

2900 |

500-3000 |

100 | 80 |

| 100 | 20 | 65 | 8.38 | ||||||

| 120 | 16 | 64 | 8.18 | ||||||

| FYS100-32 | 60 | 36 | 58 | 10.15 |

18.5 |

2900 |

500-3000 |

80 | |

| 100 | 32 | 66 | 13.21 | ||||||

| 120 | 28 | 65 | 14.09 | ||||||

|

FYS100-50 |

60 | 56 | 60 | 15.26 |

22 |

2900 |

500-3000 |

65 | |

| 100 | 50 | 68 | 20.04 | ||||||

| 120 | 44 | 67 | 21.47

|

||||||