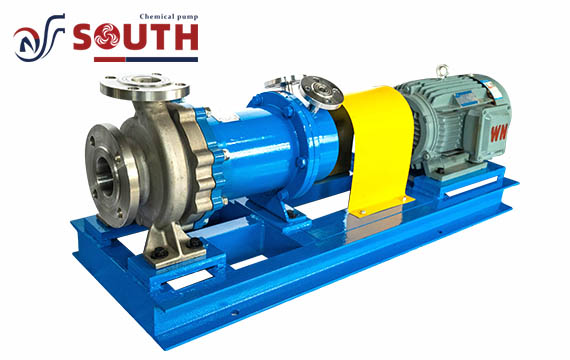

Designed instruction of IHF single stage single suction lining fluorine plastic chemical centrifugal pump

The international standard ISO2858 is an important standard for IHF single-stage single-suction horizontal fluorine plastic centrifugal pump in the design process, both the structure and performance are applicable to most countries in the world.

In addition, in the production, lining fluorine plastic chemical centrifugal pump also integrates the advanced manufacturing process of non-metallic pump, pump body, pump cover and impeller are used with fluorine lining technology, has a strong corrosion resistance.

The shaft seal of lining fluorine plastic chemical centrifugal pump uses the advanced bellows mechanical seal, installed on the outside of the sealing cavity, so that it is able to accommodate the different shapes of the sealing surface.

Outside using advanced bellows mechanical is easy to disassemble, and more convenient to remove, which can directly adjust and maintain the machine seal, this design greatly improves the service life and working efficiency of the centrifugal pump.

The static ring material of fluorine plastic chemical centrifugal pump is silicon carbide, ring is also filled with fluorine material, with good mechanical strength, corrosion resistance of centrifugal pump is incomparable.

The inlet and outlet of the fluorine plastic chemical centrifugal pump are reinforced with cast steel body, it helps to improve the stability and pressure of pump operation.

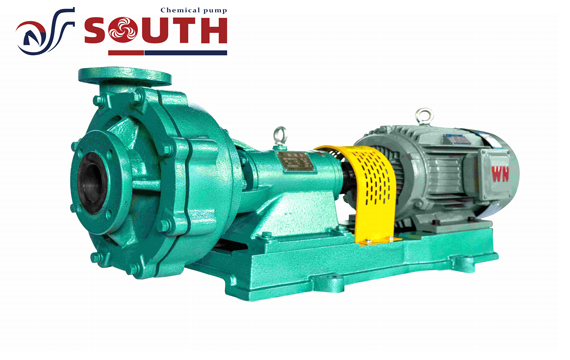

Practice has proved that the high temperature resistance of the pump material is also very good, it can withstand the temperature range of-20℃-180℃, and is not easy to aging, it is very popular in the field of chemical industry.

Advantages of lining fluorine plastic chemical centrifugal pump

Excellent corrosion resistance: the overflow parts of the centrifugal pump are lined with fluorine technology and have excellent resistance to corrosive chemicals.

No leakage: lining fluorine centrifugal pump is equipped with advanced mechanical sealing, isolating the contact with the outside world, environmental protection and pollution-free.

Convenient maintenance: lining fluorine centrifugal pump has reasonable structure, easy to dismantle, can long-term stable operation, and reduce maintenance cost.

Smooth operation and high efficiency: lining fluorine centrifugal pump ensures efficient fluid transmission while minimizing friction and wear. its rational structural design helps to improve its overall performance and service life.

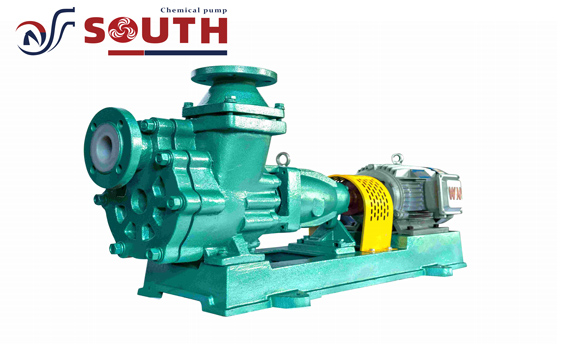

Application areas of IHF single stage single suction lining fluorine plastic chemical centrifugal pump

IHF single-stage single-suction lining fluorine plastic chemical centrifugal pump can withstand all kinds of harsh environments. In the field of medicine, because the centrifugal pump has strong corrosion resistance and no leakage characteristics, so in the delivery of liquid, it can ensure the purity and no pollution of the liquid, to meet the aseptic requirements of this industry.

In chemical production, some corrosive media, toxic and harmful media, high temperature media, flammable and explosive media are common, media transport, preservation is essential, at this time, lining fluorine plastic chemical centrifugal pump is just suitable, its corrosion resistance, no leakage characteristics is safer, and efficient.

In the textile printing and dyeing industry, the lining fluorine centrifugal pump can transport a variety of dyes, the production of wastewater to the designated place, when some mechanical equipment needs to cool down, the centrifugal pump can transport cooling water, so the centrifugal pump is also essential for the textile industry.