MAGNETIC DRIVEN PUMP FACTORY

South Magnetic Pump set the industry standard for performance excellence.

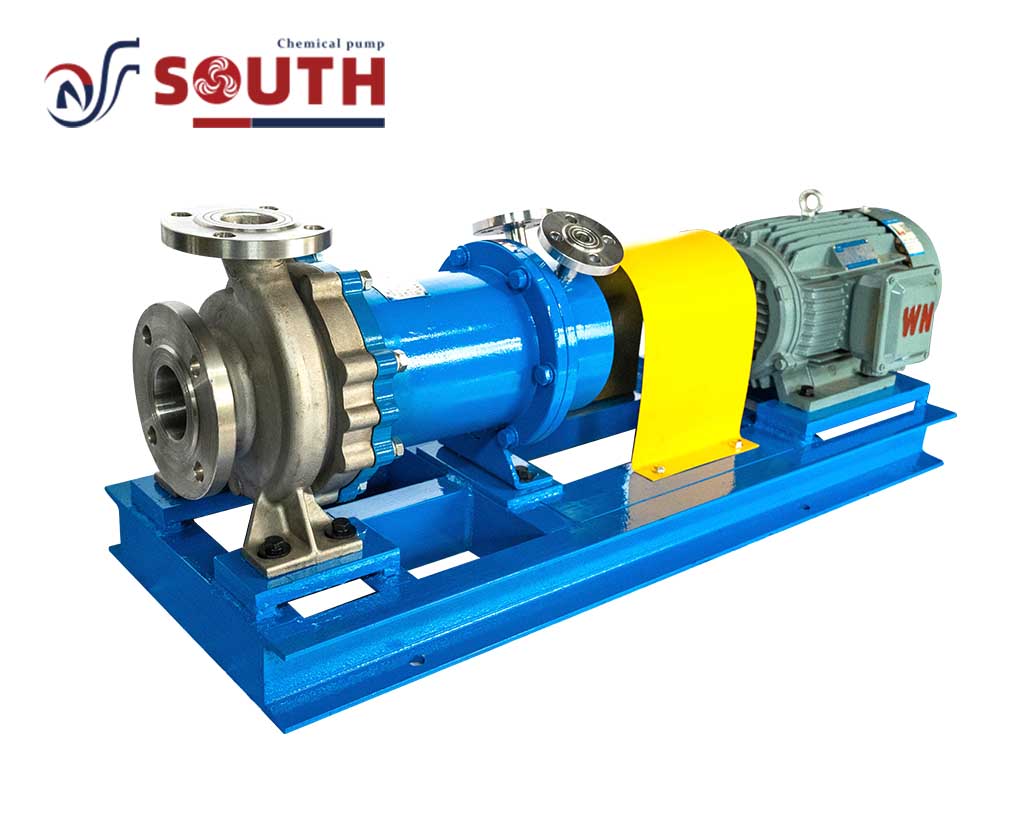

Lined-in Fluorine Non-Leakage Magnetic Pump

- Pump body material: HT200+F46 or HT200+PFA for high temperature A dovetail groove is set inside the pump body and a reinforcement hole is set at the outlet. This prevents the lining from falling off when not used for a long time or under negative pressure conditions.

- Inner rotor and impeller: Material Q235+F46 or Q235++PFA for high temperature

- Isolation sleeve: Material F46 (PFA) + ABS (carbon fiber)

- The pump shaft, sleeve, and stationary ring are all made of fluorine-resistant and wear-resistant pressure-free silicon carbide SSIC.

- The dynamic ring is filled with poly tetra fluoro ethylene(PTFE).

What is Magnetic Pump?

Magnetic drive centrifugal pump (referred to as magnetic pump) is a new type of pump that applies the principle of modern magnetism and realizes contactless transmission of torque by using the magnetic drive of permanent magnets, that is, when the motor drives the outer rotor assembly (i.e., the outer magnets) to rotate, the magnetic lines of force of the magnetic field pass through the isolation sleeve to drive the inner rotor assembly (i.e., the inner magnets) and the impeller to rotate synchronously, and the medium is enclosed in the stationary isolation sleeve to achieve the new type of industrial centrifugal pump that is leakage-free and pollution-free. The new industrial centrifugal pump is free of leakage and pollution. Completely solved the mechanical seal drive centrifugal pump shaft seal leakage drawbacks.

Some product , if they are industry product, you can put ” What is xxx” as heading, and write some basic meaning and features of the product, but if this page is about service, and 100% commercial product, then heading can be ” Your Xxxx Manufacturer” or just put a “Brand name +product name” as headingLorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua. Quis ipsum suspend.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua. Quis ipsum suspend. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua. Quis ipsum suspend. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua. Quis ipsum suspend. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua. Quis ipsum suspend.

Hot Products

Main Product Introduction

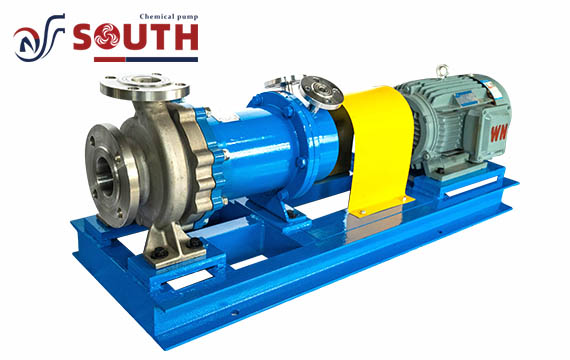

Lined-in Fluorine Non-Leakage Magnetic Pump

Product designed instructions

Fluorine-lined non-leakage Magnetic Driven Pump is based on the company’s long-term technical accumulation and the reference to the advanced foreign technology and design research and development of highly efficient energy-saving magnetic pump.

Advantages:

Absolutely no leakage, anti-dry wear, anti-cavitation, effectively reduce the irreversible damage to the pump caused by misoperation, and reduce the economic losses of the enterprise; Small size, high head, easy to disassemble and maintain; High efficiency and low energy consumption;

Lined-in Fluorine Plastic Self-Priming Magnetic Driven Pump

Product designed instructions

These series fluorine plastic magnetic self-priming pump is a combination of magnetic pump and self-priming pump all the characteristics of both magnetic pump leak proof function and self-priming function of self-priming centrifugal pump, self-priming pump dada 4m. ls a level below the pump inlet, the best choice for transporting the corrosive medium, can take the place of submerged pump.

Pump Usage:

Applicable to transport inflammable and explosive volatile, poisonous and harmful, valuable and highly corrosive cleaning medium;Such as any concentration of acid and alkali, salt.solvent, strong oxidizer, etc.

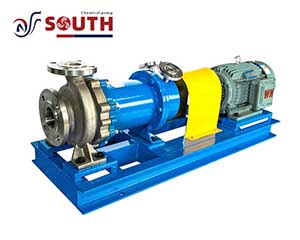

Stainless Steel Magnetic Driven Pump

(1)Direct-connected magnetic pump

①Direct-connected magnetic pump (conventional structure):

used for media below 75°C.

Features: small footprint, no need to adjust the coupling alignment.

②Air-cooled direct-connected magnetic pump:

used at 75℃-130℃ (high temperature magnet)

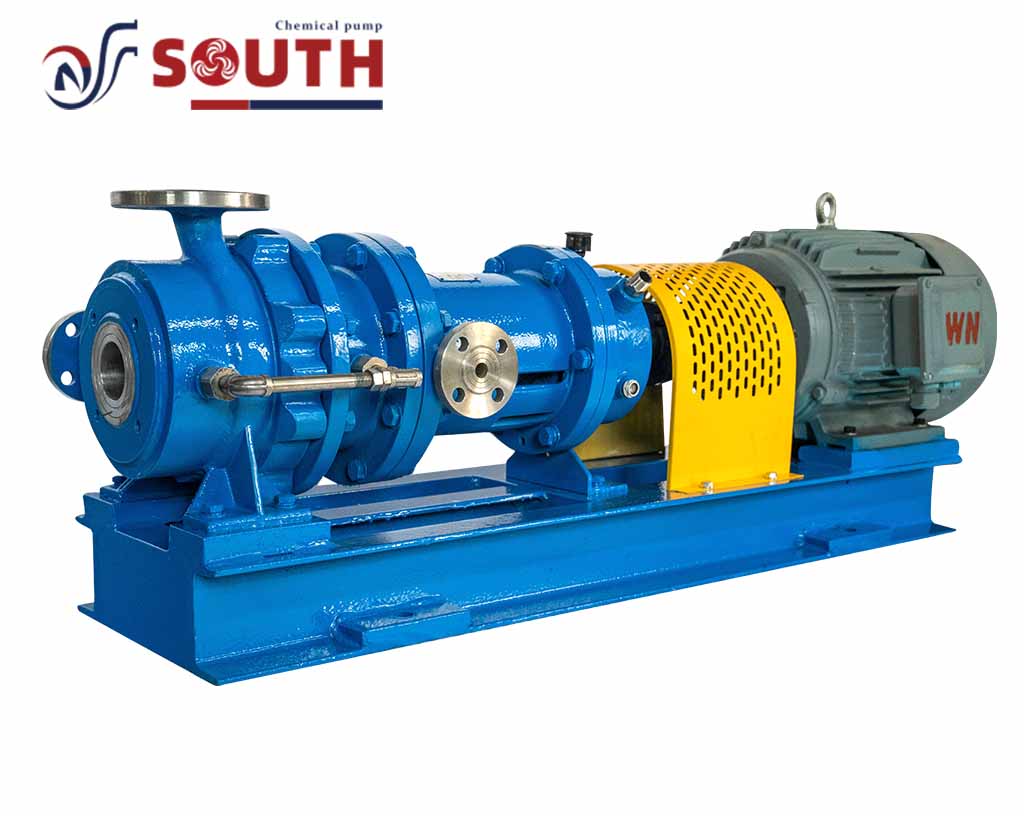

(2)Split magnetic pump (bearing box) :

Used for media below 150℃, and high temperature magnets are used for media above 100℃

High temperature stainless steel magnetic pump

Split high temperature stainless steel magnetic pump(conventional structure):

Used for 120℃-200℃ air cooling, water cooling

High temperature and high pressure magnetic pump (compensation ring structure).

Used for temperature resistance above 200℃, equipped with metal spiral wound gasket, water cooling

Direct-connected stainless steel magnetic pump

Direct-connected single pump body heat preservation magnetic pump:

Used for crystallization medium below 75℃

Direct-connected double-layer insulated stainless steel magnetic pump:

Pump body and pump cover insulation type, used for media that are easy to crystallize and need insulation below 120℃ (high temperature magnet).

Directly connected stainless steel magnetic self-priming pump

★ Technical Parameters

Mouth diameter: 25-300

Flow rate: 2 m³/h ~ 1200 m³/h

Lift: 2m ~ 125m

Speed: 2950r/min 1450r/min

Operating Temperature: -10℃ ~ 120℃

Operating Pressure: ≤25 MPa

Pump Diameter:25-150mm

Working Temperature:-20-150

Flow Capacity Range:3m³/h-250m³/h

Materials Range:Lined=in FEP(F46),PFA

Pump diameter:32mm-30mm

Working temperature:-20-160

Flow capacity range:15m-125m

Material range:Lined-in FEP(F46), PFA

Mouth diameter: 25-300 Flow: 2m³/h ~ 1200m³/h Lift: 2m ~ 125m Speed: 2950r/min 1450r/min Operating Temperature: -10℃ ~ 120℃

Direct-connected magnetic pump

①Direct-connected magnetic pump:

used for media below 75°C.

Features: small footprint, no need to adjust the coupling alignment.

②Air-cooled direct-connected magnetic pump: used at 75℃-130℃

Used for media below 150℃, and high temperature magnets are used for media above 100℃ Application fields: Biological medicine; Petrochemical; Mining; Metallurgy;Textile printing ; Dyeing; Electricity; Food; Paper making;

Used for 120℃-200℃ air cooling, water cooling

Pump usage:

Applicable to transport inflammable and explosive volatile,poisonous and harmful, valuable and highly corrosive cleaning medium

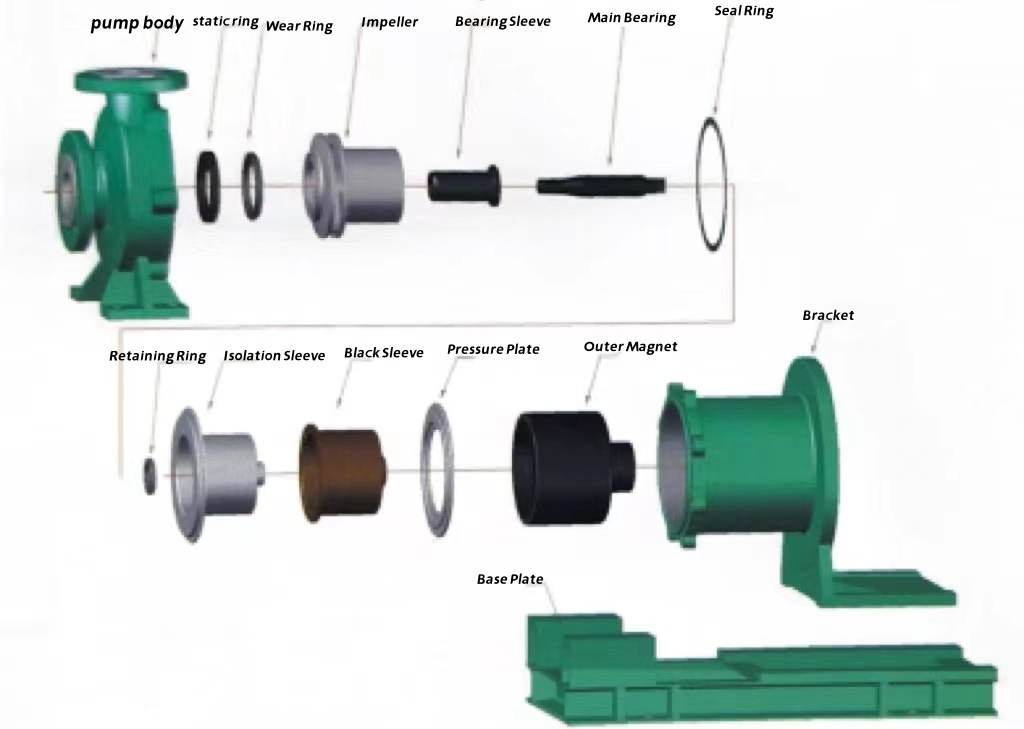

Three Dimensional Figure and Material Structure of Lined-in Fluorine Non-Leakage Magnetic Pump

*The impeller and the inner magnetic steel are designed as an integral structure to avoid jumping during operation, and the impeller nut is omitted to avoid the nut loosening caused by water hammer during shutdown;

*The impeller and the rotor are connected as a whole, and are pressed into shape at one time, which also avoids the phenomenon of slipping at the connection between the impeller and the shaft due to excessive specific gravity or frequent jumping of the medium;

*Bearings are designed on the pump body to fix the two ends of the rotor shaft on the pump body bearing and the isolation sleeve assembly bearing respectively. When the impeller is running, the rotor shaft is stationary, which effectively avoids the phenomenon of broken shaft;

*The pump cover design is removed to avoid the phenomenon of lack of liquid caused by the medium blocking the pump cover hole and preventing the medium from entering the isolation sleeve.

Applications

Q&A about Mag Pmup

Do you accept customized selection service for your magnetic pumps?

Yes, our factory specializes in providing customers with a full range of customized magnetic pump selection services. No matter how special your site conditions are, we can customize the design according to your specific needs to ensure that the performance of the pump perfectly matches your application scenario.

How do my site conditions affect the selection of a magnetic pump? What specific information do I need to know?

Site conditions are critical to the selection of a magnetic pump. We need to know if your site is indoors or outdoors, as this will affect the pump’s protection class and material selection.

In addition, the following points need to be clarified:

Conveying medium: Please tell us what specific medium you will convey, because different mediums have different requirements for pump materials, seals and corrosion resistance.

Specific gravity of the medium: the specific gravity of the medium directly affects the selection of the pump, especially the power and efficiency of the pump.

Whether containing particles and impurities and liquid purity: media containing particles and impurities need to choose a good abrasion resistance of the pump body and overflow components, and to ensure that the sealing system can effectively prevent leakage.

Flammable and explosive: If the medium has flammable and explosive properties, we will pay special attention to the safety design of the pump, such as explosion-proof motor, electrostatic protection.

Corrosiveness: the corrosiveness of the medium determines the choice of materials for the pump body and overflow components, such as stainless steel, titanium alloy and other corrosion-resistant materials used.

Temperature, pressure, flow and head requirements: these parameters are the basis of pump selection, directly affecting the pump size, power and performance curve. Please provide the exact range of values so that we can make accurate selection.

If my medium contains small particles but I need the pump to run stably, what is your solution?

For media containing small particles, we usually recommend the use of highly wear-resistant materials for the overflow parts, such as cemented carbide or ceramic coating, etc., and optimize the internal structure design of the pump to reduce the wear of particles on the pump body. At the same time, we will also consider installing a filter at the inlet of the pump to remove large particles of impurities in the medium in advance, to protect the pump body from damage and to ensure the stable operation of the pump.

What are the safety measures for magnetic pumps for flammable and explosive media?

For flammable and explosive media, we take multiple safety measures to ensure the safe operation of the pump: first of all, the use of explosion-proof motors, to ensure that the motor in the flammable and explosive environment can still work normally and will not cause danger; secondly, optimize the sealing design of the pump body, the use of high-performance sealing materials and technology, to prevent the leakage of the medium; at the same time, it will also set up an anti-static coating on the outside of the pump body or grounding device, effectively eliminating the accumulation of static electricity, reducing the risk of explosion. Reduce the risk of explosion. In addition, we will also provide customers with detailed safety operating procedures and maintenance guidelines to ensure that users strictly comply with safety norms in the process of use.