Suitable for diverse industries and processes requiring no leakage or contamination, the chemical magnetic pumps can be customized with various corrosion-resistant materials to meet specific working conditions

Overview:

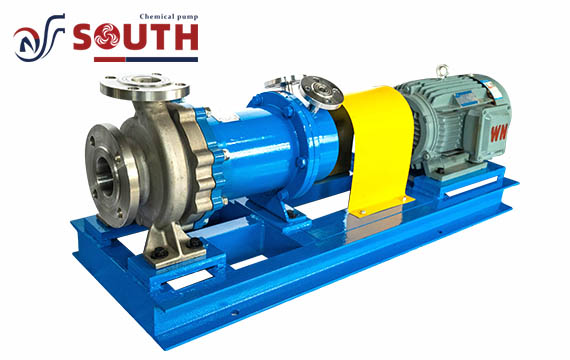

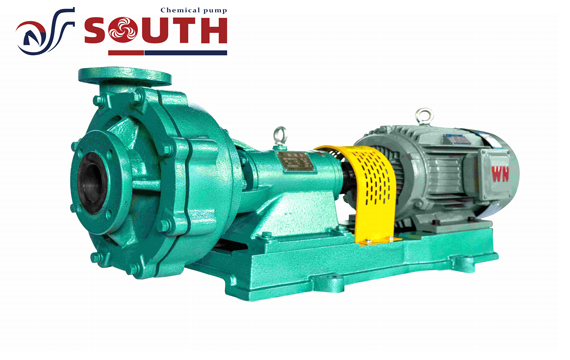

NMQ-G series magnetic pump (referred to as NMQ-G magnetic pump) is a high-temperature and high-pressure magnetic pump developed by our company for the field of heavy chemical industry. This series of magnetic pump adopts high-temperature-resistant magnetic steel, which will never be demagnetized below 350 oC, and the friction side adopts temperature compensation technology, which effectively solves the problem of damage to the pump parts due to thermal expansion and contraction and can be equipped with friction side of different materials according to the working conditions; the isolation sleeve adopts advanced circular arc shape technology. Adopting advanced circular arc technology, it is 1.2 times of the pressure resistance of traditional isolation sleeve, and various bearing box forms ensure safe operation under different working conditions and temperatures, and the building block structure makes it easier for users to maintain.

Mag Pump Product Description:

- Adopts ISO2858 and HG/T2730 standards, the pump interface size is in line with the replacement of IH, CZ and other chemical pump types, with good intermixing, high efficiency and low vibration.

- Adopts samarium cobalt permanent magnet material as inner and outer magnets, with high magnetic efficiency and strong resistance to high temperature.

- Building block structure is very easy to disassemble and repair, greatly reducing the professional requirements for maintenance personnel.

- Can be configured with idling protector according to user requirements to avoid damage problems caused by idling.

- Absolutely no leakage completely solve the leakage problem of sealing pumps, is also the best product to replace the shielding pump.

High temperature stainless steel magnetic pumps Usage:

Applicable fields: environmental protection, petrochemical, food, biopharmaceutical, electric power, mining and metallurgy, textile printing and dyeing, aerospace and other industries, such as oil refineries, ethylene plants, natural gas processing plants, various types of chemical plants, pharmaceutical plants, nuclear fuel plants, nuclear power plants.

Applicable processes: clean, flammable, explosive, volatile, toxic, high temperature, high pressure, valuable liquids and other requirements of no leakage and the medium does not allow the sealing of the occasion of pollution.

Pump Material:

Pump overflow parts according to the use of working conditions and user requirements can be used, such as: 304, 304L, 302, 321, 316, 316L, 904, titanium alloy, Hastelloy, nickel-based alloys and other types of corrosion-resistant materials. If there are special requirements, the unit can be designed and manufactured according to the working conditions.