Chemical Pumps Manufacturer Since 1999

Chemical Pumps for Transfer Of the Aggressive Process Liquid & Precious Fluids

As a chemical pump supplier with more than 25 years of experience, South Chemical Pumps specializes in the safe and efficient transfer of corrosive and valuable fluids and understands the importance of customizing reliable fluid transfer solutions.

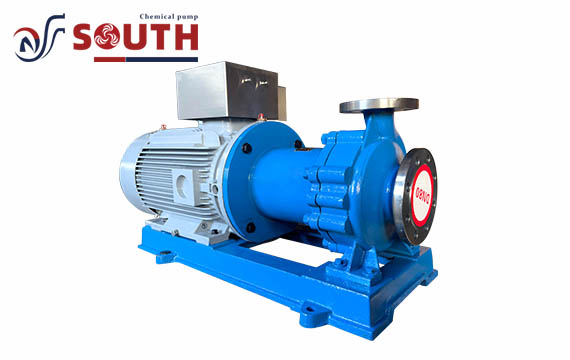

South Chemical Pumps designs and manufactures chemical pumps that are professionally engineered to ensure the stable transfer of corrosive liquids and valuable fluids. Chemical Pumps are often made from corrosion-resistant materials such as stainless steel or fluoroplastics, but it is important to ensure that these materials are fully compatible with the specific chemical composition of the fluids in your process. Based on the different design, structure and working principle, Chemical Corrosion resistant pumps are subdivided into two categories: Centrifugal Pumps and Magnetic Drive Pumps.

South Pumps will accurately match the chemical pump solution that best suits your needs based on the characteristics of the medium being pumped, the site environment, temperature, pressure, flow rate and head.

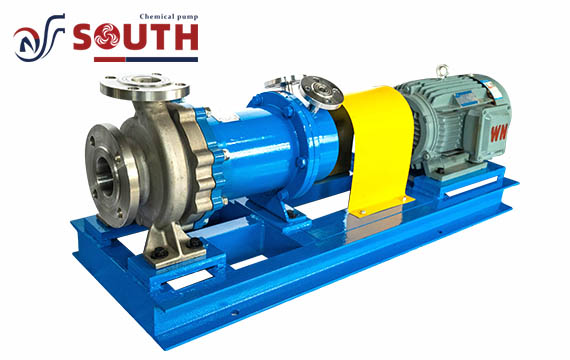

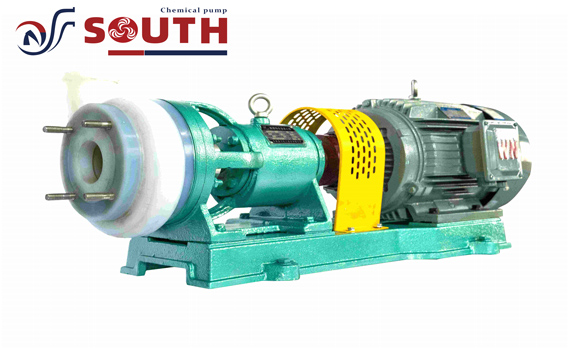

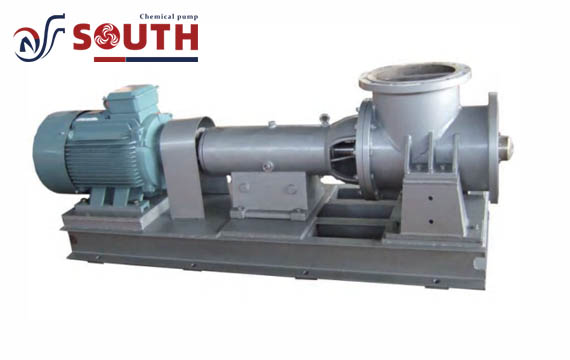

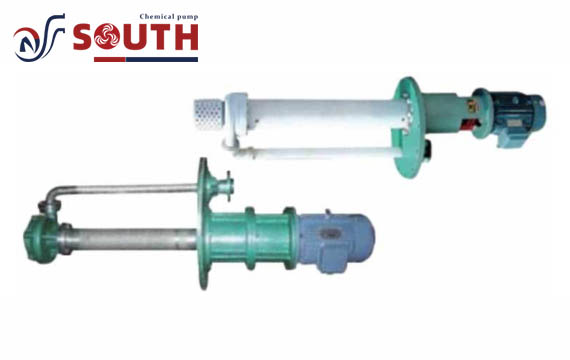

Magnetic Drive Pumps

Magnetic drive pumps, also known as magnetically driven pumps, use a magnetic coupler to transfer fluid without any physical contact between the motor and the pump. Ideal for transferring hazardous and corrosive fluids or applications requiring zero leakage.

Need help selecting the right pump for your application?

Are you looking for low-maintenance chemical pumps that won't corrode or fail?

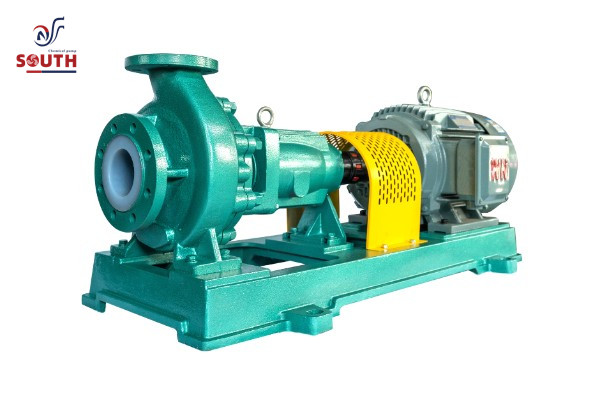

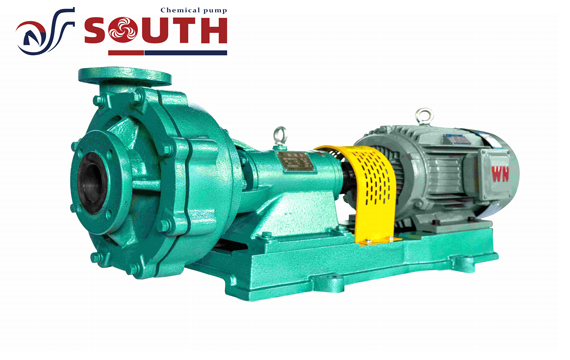

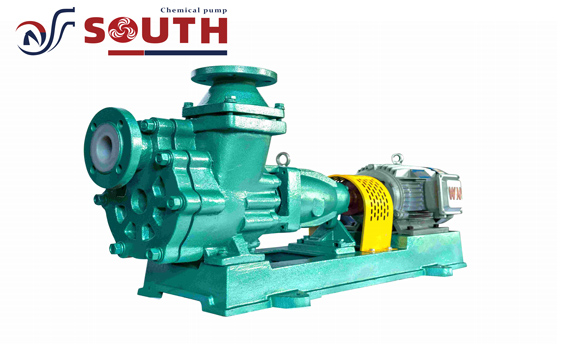

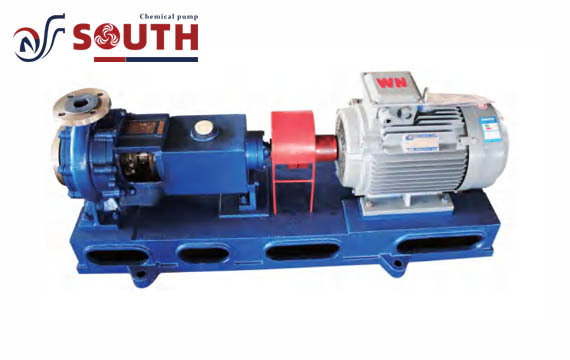

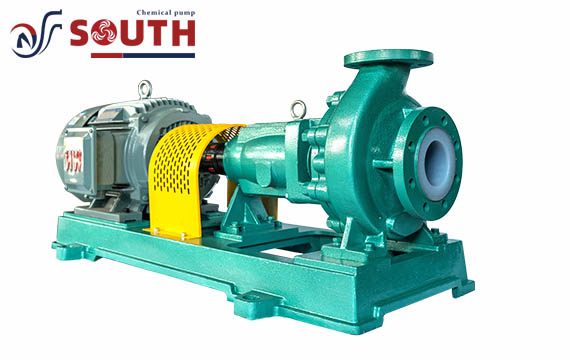

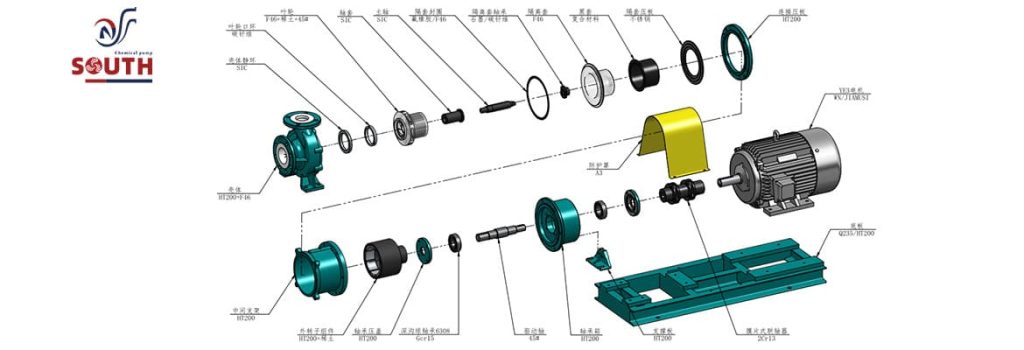

Chemical Centrifugal Pumps

Centrifugal pumps are the most commonly used type of chemical pumps. Centrifugal pumps are reliable, efficient and economical, and are suitable for fluids with low to medium viscosity and low solid content.

Benefits of South Chemical Pump Range

-

Corrosion&abrasion resistance

Due to the need to handle highly corrosive and abrasive liquids, South Chemical Pumps are manufactured with special materials such as stainless steel, alloy steel, plastic composites (e.g., fluoroplastics), which can effectively resist the erosion of liquids and prolong the service life of the pumps.

-

Excellent sealing performance

For the characteristics of corrosive liquids and precious fluids, South Chemical Pumps usually use high-performance seals, such as mechanical seals, magnetic seals, etc., to ensure that the pumps are leak-free during operation, to protect the environment and the safety of the operators, and at the same time, to avoid fluid loss.

-

High precision and stability

South Chemistry Pumps feature high-precision flow regulation and pressure control to ensure stability and accuracy in the transfer of precious fluids. In addition, pumps are designed to minimize vibration and noise and improve smooth operation.

-

High safety performance

Considering the potential dangers of handling liquids, South Chemical Pumps are designed with full consideration of safety factors. For example, the use of explosion-proof motors, overheating protection, overload protection and other safety measures ensure that the pumps can automatically shut down and sound an alarm in abnormal situations to avoid accidents.

Applications of Chemical Pumps

Chemical Industry

Production processes: Used to transfer and process various chemicals, including acids, bases, solvents, and catalysts.

Material handling: Used to transport raw materials, intermediates, and finished products.

Wastewater treatment: Used to pump and treat wastewater containing hazardous chemicals.

Pharmaceutical Industry

Drug manufacturing: Used to transfer and process pharmaceutical ingredients and formulations.

Sterile production: Used in aseptic environments to handle sterile liquids and prevent contamination.

Waste management: Used to pump and treat pharmaceutical waste.

Pulp and Paper Industry

Process water: Used to pump and treat process water used in pulp and paper production.

Chemical handling: Used to transfer and process chemicals used in the pulping and papermaking process.

Wastewater treatment: Used to treat wastewater from pulp and paper mills.

Other Industries

Electronics manufacturing: Used to transfer and process chemicals used in semiconductor and electronics manufacturing.

Metallurgy: Used to transfer and process acids and other chemicals used in metal processing.

Environmental remediation: Used to pump and treat contaminated groundwater and soil.

Custom pump solutions,

tailored to your needs

Contact South Chemical Pump Today to Discuss Your Chemical Pump Needs

South Chemical Pumps is not limited to a single standard model of chemical pumps. We can customize the perfect solution for your specific chemical fluid and needs.

Contact South Pump

Get a quote now for a chemical pump suitable for your application