What is magnetic-driven pump?

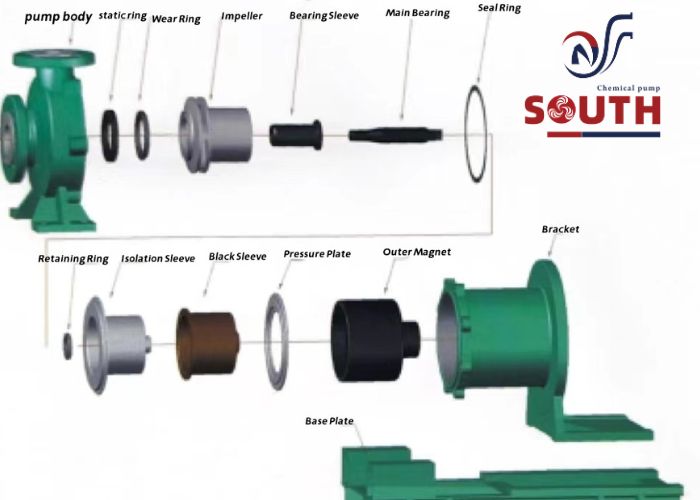

Magnetic drive pump is a new type of pump. That applies the principle of modern magnetism. And realizes contactless transmission of torque. By using the magnetic drive of permanent magnets. That is when the motor drives the outer rotor assembly (i.e., the outer magnets) to rotate. The magnetic lines of force of the magnetic field pass through the isolation sleeve to drive the inner rotor assembly (i.e., the inner magnets). And the impeller to rotate synchronously. The medium is enclosed in the stationary isolation sleeve to achieve the new type of industrial centrifugal pump. That is leakage-free and pollution-free. The new industrial centrifugal pump is free of leakage and pollution. The mechanical seal drive centrifugal pump shaft seal leakage drawbacks have been completely solved.

Magnetic pumps are ideal pumps for eliminating the phenomenon of running, risking, dripping, and leaking in the chemical process. Eliminating environmental pollution, creating “leakage-free” “workshop” and “leakage-free factory”. And realizing safe and civilized production. Widely used in petroleum, chemical, pharmaceutical, printing and dyeing, electroplating, food, new energy, and environmental protection. And other industries that transport corrosive liquids that do not contain iron impurities. Especially suitable for flammable, explosive, volatile, toxic, and precious liquids.

II.Different magnetic pumps introduction

1. Magnetic Driven Pump

The products are mainly used for the transportation of strong corrosive media such as strong acids and alkalis and are mainly used for the transportation of pharmaceuticals, environmental protection, petrochemicals, new energy, new materials, sewage treatment, and precious media.

Advantages:

①Absolutely no leakage, anti-dry abrasion, anti-cavitation, effectively reduce the irreversible damage caused by misoperation to the pump, while reducing the economic losses of enterprises;

②Small size, high head, easy to disassemble, easy to maintain;

③High efficiency and low energy consumption;

④Maximum flow rate of 400m³/h. It is the largest fluorine-lined magnetic pump in China at present, which is used for the transportation of high-concentration sulfuric acid and hydrochloric acid medium;

⑤Maximum temperature resistance up to 160 degrees.

2. Stainless Steel Magnetic Driven Pump

The products are mainly used in fine chemicals, environmental protection, pharmaceuticals, new energy, new materials, sewage treatment, and the transportation of precious media.

Advantages:

①Absolutely no leakage, anti-dry wear, and anti-cavitation effectively reduce the misoperation of the pump to cause irreversible damage, while reducing the economic losses of enterprises;

②15% increase of magnetic torque under the same size;

③Increase the efficiency of the whole machine by 5~10 percentage points;

④Conveying medium temperature up to 320℃;

⑤Single manufacturing capacity up to: 600m³/h flow, maximum head 50m, supporting motor up to 200kw.

III. Application of magnetic driven pump

1. Magnetic-driven pump in the chemical field

Corrosive liquid transportation. Magnetic pumps are often used to transport all kinds of corrosive liquids, such as acid, alkali, salt, and so on. As the magnetic pump has no mechanical seal, it will not produce leakage, thus avoiding environmental pollution and material waste.

Special media handling: In the chemical process, magnetic pumps are able to handle special media such as high temperature, toxic, flammable, and explosive to ensure production safety.

2. Pharmaceutical field

Pharmaceutical manufacturing and conveying. The non-leakage characteristics of magnetic pumps ensure the purity and safety of drugs, to meet the pharmaceutical industry’s high demand for hygiene and quality.

Customized design. Magnetic pumps can be customized according to the needs of the pharmaceutical process to adapt to the special conveying needs of different drugs.

3. Food industry

High-viscosity liquid conveying: In the process of food processing and conveying magnetic pumps can convey high-viscosity liquids such as sauces, jams, syrups, etc. to ensure the smoothness and safety of the production process.

Hygienic guarantee: Magnetic pumps have no mechanical seals, which prevent bacteria and other contaminants in food from entering the pump body, thus guaranteeing the hygienic quality of food.

4. Environmental protection field

Wastewater treatment: Magnetic pumps are used to treat all kinds of wastewater, waste liquid, etc. Its non-leakage and non-pollution characteristics make it effective in preventing secondary pollution in the process of environmental protection.

High efficiency and energy saving: the high efficiency and energy saving characteristics of magnetic pumps also make them have a broad application prospect in the field of environmental protection.

5. Scientific research experiment field

Precision experiments: In the field of scientific research experiments, magnetic pumps are used in various precision chemical reactions and experimental processes, and their high precision and stability can ensure the accuracy and reliability of the experimental results.

Non-leakage characteristics: The non-leakage and non-pollution characteristics of magnetic pumps are also in line with the high standard of equipment required for scientific research experiments.

6. Electric power field

Cooling water transfer: In the power industry, magnetic pumps are used to transfer cooling water, circulating water, and other media to ensure the normal operation of power equipment.

Special Liquid Handling: Magnetic pumps can also handle some special liquids in nuclear power plants to meet the special needs of the power industry.

7. Other fields

· Electroplating industry:

Magnetic pumps are capable of handling various chemicals and are suitable for conveying corrosive liquids in the electroplating industry.

· Semiconductor manufacturing:

In the semiconductor industry, magnetic pumps can convey high-purity and dust-free liquids. Avoid possible particle contamination from mechanical seals.

· Shipbuilding industry:

Magnetic pumps can convey fuel oil, lubricating oil, and other media.

· Metallurgical industry:

Magnetic pumps can convey high-temperature molten metals, etc.

IV. Why choose South Magnetic Pump Factory?

①A complete range of various types of machining equipment effectively ensures the precision of each spare part.

②Tidy working environment and serious implementation of standardized production management.

③National B-level precision testing center. Ensuring the parameters that customers required.

④When the spare parts are in and out of the warehouse, they are subject to strict inspection and testing to ensure quality.

⑤Modernized warehousing management effectively improves production efficiency and also guarantees the timeliness of after-sales service.

⑥Fast logistics and distribution services. Each pump will check several times before the box up and sent out.

V. Summary

Magnetic driven pump is the application of modern magnetic theory. The use of permanent magnets to achieve Non-contract indirect transmission of a chemical process pump. When the external rotor motor (outside magnetic steel drives assembled rotates through the magnetic lines of force within the rotor drive isolation kit) inside magnetic steel.

Synchronous rotating assembly with the impeller, liquids stay in a closed static isolation kit. So that without leakage of the purpose pumping mediums, solve the mechanical transmission pump seal leakage. It uses a static seal instead of a dynamic seal. So that it can keep the flow components in the seal station. It solves the other problems like running, emitting drip, and so on. Magnetic-driven pumps have two features of simple structure. Low noise, stable running, safety environment protection. It is first choosing to transfer without leakage in industrial fields.

Anhui South Chemical Pump was established in 1999. As a professional chemical pump valve R & D, production, sales, export, and service in one of the national level high -new technology enterprises.

Our company has more than twenty years of experience in the production and design of fluorine-lined centrifugal pumps, fluorine-lined non-leakage magnetic pumps, stainless steel non-leakage magnetic pumps, corrosion, and abrasion-resistant mortar pumps, etc. South Magnetic Pump Manufacture has more than 30 independent intellectual property rights of various types.