When it comes to liquid delivery such as chemicals. Choosing the right pump is essential to ensure safety and efficiency. Different chemicals require specialized materials and technologies to prevent corrosion.

In this article, South Chemical Pump will explore the most commonly used chemical pumps for conveying various corrosive media such as sulfuric acid, hydrochloric acid, nitric acid, etc. Understanding the specific needs of chemical processes. We will help you choose the right pump.

The following are some key points for selecting commonly used media for our chemical pumps:

(1) Chemical pumps for transporting sulfuric acid

Sulfuric acid is one of the most corrosive media. It is also a crucial raw material in industrial processes. Sulfuric acid is widely used. Sulfuric acid of different concentrations and temperatures has a very different effect on the corrosion of centrifugal pumps. Electric centrifugal pumps made of carbon steel and cast iron have good corrosion resistance to concentrated sulfuric acid with a concentration greater than 80% and a temperature of less than 80°C.

But carbon steel pump is not suitable for high-speed flowing sulfuric acid. It is also not suitable as a material for pumps and valves. Ordinary stainless steel chemical pumps such as 304 and 316 also has limited uses for sulfuric acid media.

Therefore, standard chemical pumps for conveying sulfuric acid are usually made of high-silicon cast iron (difficult to cast and process) and high-alloy stainless steel (No. 20 alloy) . However, it is difficult to process and the material is expensive, so it is not favored by people.

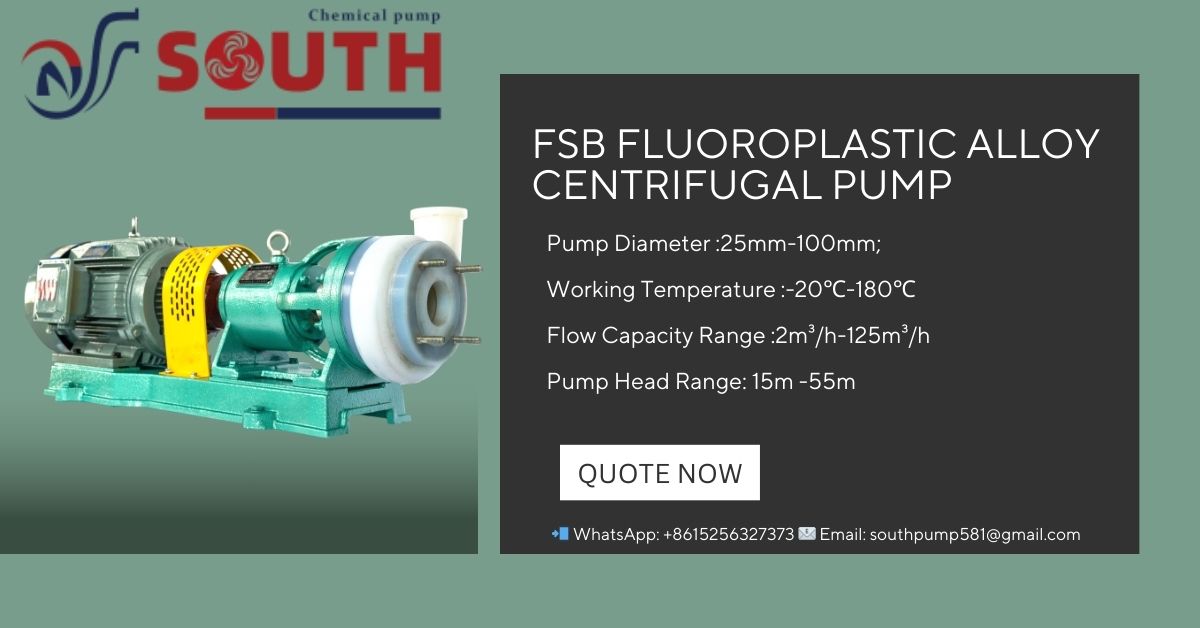

Fluoroplastic alloy self-priming pump has very good resistance to sulfuric acid. Using a fluorine-lined pump (F46) is a better choice. Applicable products include: South Pump fluorine-lined pump, strong corrosion-resistant centrifugal pump, fluorine plastic magnetic pump, etc.

(2) High Quality Chemical pumps for transporting hydrochloric acid

Hydrochloric acid, most pumps are not resistant to hydrochloric acid corrosion (including various stainless steel pumps). Molybdenum-containing high silicon iron centrifugal pumps can only be used for hydrochloric acid below 30% at 50°C.

In contrast to metal materials, most non-metallic materials have good corrosion resistance to hydrochloric acid. As a result, lined rubber pumps and plastic pumps (such as engineering plastics, fluoroplastics, and others) are ideal options for transporting hydrochloric acid.

Applicable products include: fluorine-lined pumps, strong corrosion-resistant centrifugal pumps, fluoroplastic magnetic pumps, etc.

(3) Good Price Chemical pumps for transporting nitric acid

Nitric acid quickly corrodes and damages most common metals. Stainless steel centrifugal pumps are widely used due to their excellent resistance to nitric acid. It has good corrosion resistance to nitric acid of all concentrations at room temperature.

The corrosion resistance of molybdenum-containing stainless steel centrifugal pump (such as 316, 316L) to nitric acid sometimes even worse. It is not better than that of ordinary stainless steel centrifugal pump (such as 304, 321). For high-temperature nitric acid, fluoroplastic alloy centrifugal pump are usually used.

Applicable products include: South Pump Company series IHF fluorine-lined pumps, FSB strong corrosion-resistant centrifugal pumps, IMD fluoroplastic magnetic pumps, etc.

(4) South Chemical pumps for transporting acidic solutions

Among organic acids, acids are the most corrosive. Ordinary steel pumps will experience severe corrosion when exposed to acetic acid at any concentration or temperature. Stainless steel centrifugal pump is an excellent material resistant to acetic acid.

Molybdenum-containing 316 stainless steel centrifugal pump can also be used for high temperature and dilute acetic acid vapor. For demanding requirements such as high temperature and high concentration acetic acid or other corrosive media, high alloy stainless steel or fluoroplastic pumps can be selected.

Applicable products include: South Pump Company series IHF fluorine-lined pump, FSB strong corrosion-resistant centrifugal pump, IMD fluoroplastic magnetic pump, etc.

(5) Classic Chemical pumps for transporting alkaline solutions

Alkali (sodium hydroxide) is generally not very corrosive, but alkaline solutions generally produce crystals. Therefore, IMD fluorine-lined magnetic pumps and NMQ stainless steel magnetic pumps with siliconized graphite mechanical seals can be selected.

(6) Standard Chemical pumps for transporting ammonia

Ammonia (ammonium hydroxide) causes minimal corrosion to most metals and non-metals, with copper and its alloys being unsuitable for use.

However, the majority of our products are well-suited for transporting ammonia and ammonium hydroxide. For example, CQF engineering plastic magnetic pumps and FSB fluorine alloy centrifugal pumps are better.

(7) Longevity Chemical pumps for transporting brine

Salt water (seawater) Ordinary steel has a low corrosion rate in sodium chloride solution, seawater and salt water, and generally needs to be protected by coating. Various types of stainless steel chemical delivery pump also have a very low uniform corrosion rate.

However, local corrosion may be caused by chloride ions, so 316 stainless steel is usually better. Such as NMQ stainless steel magnetic pump.

(8) Durable Chemical pumps for transporting alcohol media

Alcohols, ketones, esters, ethers Common alcohol media include methanol, ethanol, ethylene glycol, propanol, etc. Ketone media include acetone, butanone, etc. Ester media include various methyl esters, ethyl esters, etc. Ether media include substances such as methyl ether, ethyl ether, butyl ether, and others. They are basically not very corrosive, so ordinary stainless steel centrifugal pump can be used.

When making specific choices, reasonable choices should be made based on the properties of the media and related requirements. It is also important to note that ketones, esters, and ethers are soluble in various types of rubber, so caution should be taken when selecting sealing materials for chemical pumps.

In summary, choosing the right chemical delivery pump requires considering performance. It is also necessary to ensure that your equipment can withstand the specific challenges posed by different corrosive media.

By correctly selecting a pump, such as a fluorine-lined pump or a magnetic drive pump, you can ensure the safety and efficiency of your operation. At Anhui South Chemical Pump, we offer a variety of customized solutions to meet your needs. For more information or help choosing the right pump for your application, please feel free to contact us!