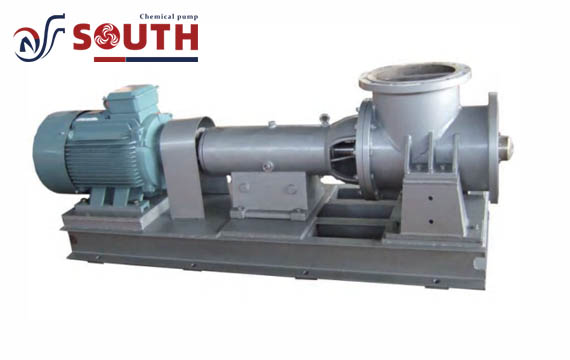

The structure design of NJL chemical axial circulation pump is cantilever type, stable operation, high efficiency and energy saving, simple structure, and convenient maintenance.

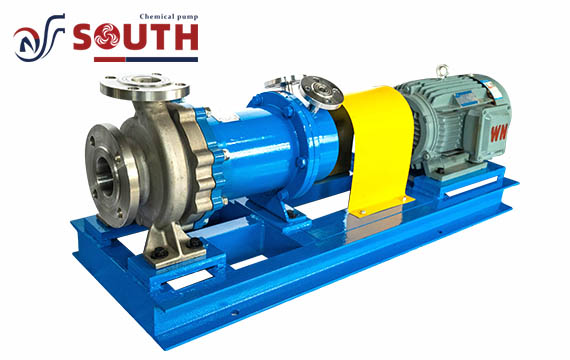

Its material is made of stainless steel, corrosion and wear resistant alloy, according to the working conditions, circulation pump can also be lined with fluorine plastic, in order to enhance its corrosion resistance.

The chemical axial circulation pump is subjected to a temperature range between-20℃-250℃, pump diameter is 350mm-1200mm, flow capacity range is 500-18000m³/h, pump head range is 2m-8m.

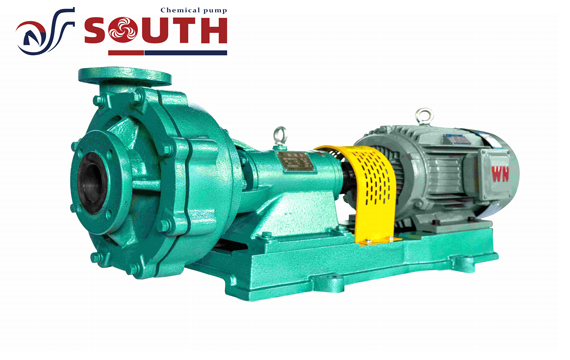

In the chemical industry, chemical axial circulation pump can be used as a forced cycle of the evaporator, in the water supply system, it can deliver domestic water at high pressure. in industrial wastewater treatment, chemical pumps also stand out for their corrosion resistance and wear resistance.

Designed instruction of NJL chemical axial circulation pump

The NJL Series Chemical Axial-Flow Pump is specifically engineered with a cantilever construction, featuring a pump body and suspension bracket that possess individual support feet securely mounted on the pump base. This configuration ensures stable pump operation, facilitating effortless maintenance while enhancing overall safety. Conforming to the GB/T13008 standard, the pump boasts remarkable capabilities, including high flow rates, substantial capacity, and a low pump head design.

The shaft seal incorporates a harmonious blend of dynamic and mechanical seals, ensuring that the pump remains leak-free during both operational and idle states. The overflow liquids flow smoothly in both horizontal (suction) and vertical (exhaust) directions, optimizing fluid handling efficiency. The standard connection method adopted is direct, simplifying installation procedures. Additionally, the pump can be customized with pulley transmission to suit the specific needs of end-users.

In terms of materials, the NJL Series Chemical Axial-Flow Pump not only utilizes stainless steel for its corrosion resistance and wear durability but also offers the option of lining with F46, PFA, or PE, depending on the varying working conditions. This versatility allows the pump to cater to diverse applications and meet the diverse requirements of clients.

Advantages of chemical axial circulation pump

Stable Cantilever Design: The pump features a cantilever structure with dedicated support feet for both the pump body and suspension bracket, ensuring stable operation and minimizing vibrations. This design also simplifies maintenance procedures and enhances overall safety.

Compliance with Industry Standards: Designed in accordance with GB/T13008 standards, the pump meets rigorous quality and performance criteria, guaranteeing reliability and compatibility with various industrial systems.

High Flow Capacity and Low Pump Head: The pump offers a combination of large flow rates and substantial capacity, coupled with a low pump head, making it suitable for a wide range of fluid handling requirements.

Dual-Seal System: The shaft seal incorporates both dynamic and mechanical seals, creating a leak-proof barrier that ensures continuous operation without leakage, even during startup, shutdown, or idle periods.

Versatile Flow Directions: The overflow liquids can flow in both horizontal (suction) and vertical (exhaust) directions, facilitating integration into various process layouts and enhancing operational flexibility.

Easy Connectivity: The pump comes with standard direct connection methods, simplifying installation and integration into existing systems. Additionally, pulley transmission can be provided upon request, catering to specific end-user needs.

Corrosion-Resistant Materials: Constructed primarily from stainless steel, the pump is inherently corrosion-resistant and wear-durable. Optional linings such as F46, PFA, or PE can be provided to further extend its applicability across different working conditions, meeting the needs of various clients.

Application areas of chemical axial circulation pump

The NJL Series Chemical Axial-Flow Pump finds extensive application across various industries, showcasing its versatility and reliability. It is ideally suited for handling a wide range of chemicals and processes, including the pumping of ammonium phosphate, phosphoric acid, vacuum salt, alumina, and caustic soda. In light industry and beyond, this pump serves as a vital component in forced circulation evaporators, functioning as both a crystallizer circulating pump and a reactor pump, catering to the specific demands of these processes.

Moreover, its usage extends to the desulfurization cycle in the non-ferrous metal smelting industry, demonstrating its capability to handle corrosive or reactive media effectively. The paper industry, acid phosphate fertilizer industry, petrochemical industry, fine chemicals, electric power generation, and metallurgy sectors also rely on the NJL Series Pump for their critical processes. Its ability to withstand harsh conditions and pump a diverse array of fluids makes it a suitable choice for water treatment (discharge) operations and mining applications, where durability and performance are paramount.

Chemical axial circulation pump performance parameters of the table

| Model No | Flow Capacity

(m3/h) |

Pump Head

(m) |

Efficiency

(%) |

Shaft power

(KW) |

Motor Power

(KW) |

Rotating Speed

(r/min) |

Diameter (mm) | |

| Inlet | outlet | |||||||

| 250NJL-2.5 | 300 | 2.5 | 60 | 3.4 | 7.5 | 980 | 250 | 250 |

| 300NJL-3 | 520 | 3 | 62 | 6.8 | 11 | 980 | 300 | 300 |

| 350NJL -4 | 1350 | 4 | 65 | 29.6 | 37 | 980 | 350 | 350 |

| 400NJL-4 | 1600 | 4 | 65 | 33 | 45 | 980 | 400 | 400 |

| 450NJL-4 | 2200 | 4 | 68 | 46.8 | 55 | 980 | 450 | 450 |

| 500NJL-4 | 2650 | 4 | 70 | 42 | 75 | 740 | 500 | 500 |

| 550NJL-4 | 4000 | 4 | 70 | 63 | 90 | 740 | 550 | 550 |

| 600NJL-4 | 4800 | 4 | 63 | 77 | 110 | 740 | 600 | 600 |

| 700NJL-3.2 | 5400 | 3.2 | 63 | 74.8 | 90 | 500 | 700 | 700 |

|

800NJL-3.7 |

6150 | 3.8 | 70 | 91 |

110 |

450 |

800 |

800 |

| 6600 | 3.7 | 65 | 102.5 | |||||

| 7200 | 3.2 | 64 | 98.1 | |||||

|

900NJL-3 |

7750 | 3.4 | 72 | 99.7 |

132 |

400 |

900 |

900 |

| 8200 | 3 | 64 | 105 | |||||

| 9000 | 2.6 | 65 | 98.1 | |||||

|

1000NJL-3.5 |

10700 | 3.7 | 64 | 168 |

200 |

380 |

1000 |

1000 |

| 11300 | 3.5 | 66 | 163 | |||||

| 12000 | 2.8 | 64 | 143 | |||||

|

1200NJL-2.5 |

12400 | 2.7 | 77 | 119 |

160 |

360 |

1200 |

1200 |

| 13500 | 2.5 | 79 | 117 | |||||

| 14800 | 2.2 | 79 | 113 | |||||

|

1500NJL-2.3 |

18500 | 2.5 | 79 | 160 |

220 |

320 |

1500 |

1500 |

| 20000 | 2.3 | 80 | 157 | |||||

| 22000 | 2.2 | 77 | 172 | |||||