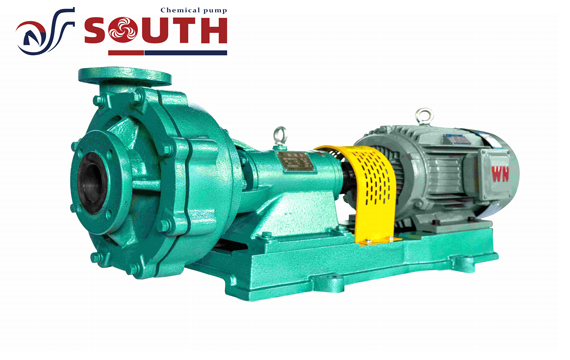

Fluoroplastic alloy centrifugal pump’s overflow parts are made of fluorine plastic, and the fluorine plastic is famous for its corrosion resistance and wear resistance, so the pump also has the same performance.

All stainless steel refractory corrosive substances, fluoroplastic alloy centrifugal pump can resist, for some expensive metals, such as titanium alloy pumps, this pump is a good substitute.

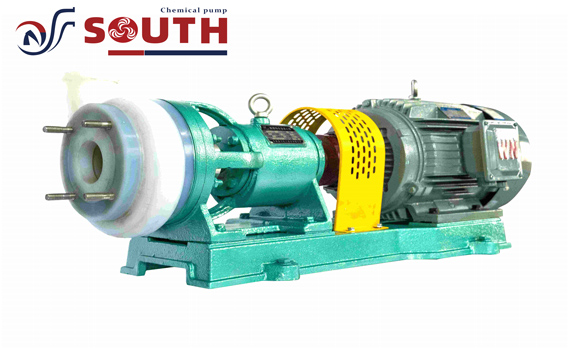

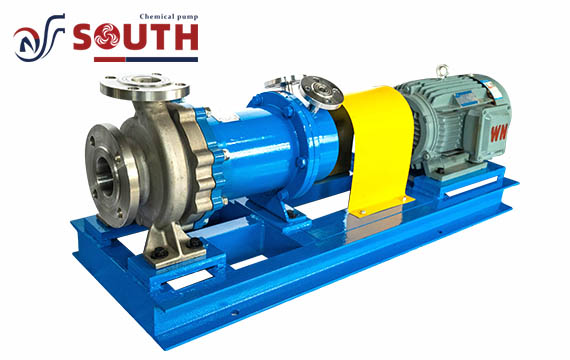

Fluoroplastic alloy centrifugal pump has two structural forms, long and short brackets, long brackets covers a slightly larger area, but the operation of the pump is relatively stable, and the life is long, suitable for electric power, aviation sewage treatment, flue gas treatment and other large industries.

Short bracket covers a small area, and the structure is simple, easy to repair, the operation is more convenient. they have their own advantages and need to be based on the actual situation.

Designed instruction of fluoroplastic alloy centrifugal pump

The FSB series fluoroplastic alloy centrifugal pump utilizes advanced pump manufacturing and processing techniques. The pump body, impeller, and pump cover are crafted with a metal core coated in fluoroplastic through high-temperature molding. The sealing system incorporates an adjustable PTFE bellows mechanical seal. The series offers two structural variations, designed for optimal performance with a robust framework, ensuring easy operation, user-friendly maintenance, and reliable service life.

Characteristics of fluoroplastic alloy centrifugal pump

Suitable for transporting various concentrations of acetic acid, phosphoric acid, formic acid, and other organic acids, as well as handling aggressive bases, strong oxidizers, reducers, and other corrosive chemicals like bromine compounds. This pump can withstand corrosive environments that would typically require the use of more costly materials such as Hastelloy or Inconel alloys, making it a cost-effective alternative to more expensive alloy pumps.

Advantages fluoroplastic alloy Centrifugal Pumps

Compatibility with Various Media: Capable of conveying different concentrations of sulfuric acid, hydrochloric acid, nitric acid, aqua regia, hydrofluoric acid, as well as strong alkalis, strong oxidizers, reducers, and highly corrosive media like chlorine ions.

High Corrosion Resistance: Offers superior resistance to corrosive media that stainless steel cannot withstand.

Cost-Effective: Provides a more economical alternative to expensive titanium alloys and Monel alloy materials.

Superior Material Selection: Utilizes materials with excellent corrosion resistance, making it suitable for handling highly corrosive substances.

Wide Application: Can be used in various industrial sectors, replacing more costly alloy pumps, with broad application potential.

Application areas of fluoroplastic alloy centrifugal pumps

Port shipping: Centrifugal pumps are vital in port activities, handling tasks such as port water distribution, ship fueling, ship bilge drainage, and the extraction of marine minerals.

Chemical manufacturing: In the chemical industry, centrifugal pumps are extensively used for the movement of liquids, mixing in reactors, and circulation in mixing tanks, serving facilities like fertilizer factories, synthetic resin producers, paint manufacturers, and pigment production plants.

Water treatment: Centrifugal pumps are commonly employed in various water management processes, including municipal water supply, drainage, sewage treatment, and irrigation. They play a key role in transporting water across different locations, such as in urban water systems, industrial water facilities, sewage treatment plants, and irrigation networks.

Miscellaneous uses: Centrifugal pumps are also indispensable in diverse sectors, such as city water supply and drainage systems, supplying water to steam locomotives, providing lubrication and cooling in machine tools, as well as in the textile industry for moving bleach and dyes, in the paper industry for transporting pulp, and in the food industry for handling products like milk and sugar.

Fluoroplastic alloy centrifugal pump performance parameters of the table

| Model No | Flow Capacity

(m3/h) |

Pump Head

(m) |

Motor Power

(KW) |

Rotating Speed

(r/min) |

Efficiency

(%) |

Shaft power

(KW) |

NPSH(m) | Diameter(mm) | |

| Inlet | outlet | ||||||||

| 25FSB-18 | 1.8 | 20 | 1.5 | 2900 | 18 | 0.63 | 3 | 25 | 25 |

| 3.6 | 18 | 25 | 0.71 | 3 | |||||

| 5 | 15 | 21 | 0.93 | 3 | |||||

| 25FSB-25 | 2 | 26 | 1.5 | 2900 | 25 | 0.59 | 3 | ||

| 3.6 | 25 | 36 | 0.68 | 3 | |||||

| 5 | 23 | 38 | 0.82 | 3 | |||||

| 40FSB-15 | 3.5 | 15 | 3 | 2900 | 21 | 0.68 | 3 | 40 | 32 |

| 5 | 15 | 26 | 0.79 | 3 | |||||

| 8 | 10 | 18 | 1.21 | 3 | |||||

| 40FSB-20 | 6 | 23 | 3 | 2900 | 30 | 1.25 | 3 | ||

| 10 | 20 | 42 | 1.30 | 3 | |||||

| 12 | 17 | 38 | 1.46 | 3 | |||||

| 40FSB-30 | 6 | 32 | 3 | 2900 | 22 | 2.38 | 3 | ||

| 10 | 30 | 31 | 2.64 | 3 | |||||

| 12 | 28 | 32 | 2.86 | 3 | |||||

| 50FSB-20 | 8 | 21 | 3 | 2900 | 40 | 1.14 | 3 | 50 | 32 |

| 12.5 | 20 | 52 | 1.31 | 3 | |||||

| 15 | 18 | 52 | 1.41 | 3 | |||||

| 50FSB-25 | 8 | 26 | 3 | 2900 | 38 | 1.49 | 3 | ||

| 12.5 | 25 | 48 | 1.77 | 3 | |||||

| 15 | 22 | 48 | 1.87 | 3 | |||||

| 50FSB-30 | 8 | 32 | 3 | 2900 | 35 | 1.99 | 3 | ||

| 12.5 | 30 | 46 | 2.22 | 3 | |||||

| 15 | 28 | 46 | 2.49 | 3 | |||||

| 65FSB-20 | 15 | 21 | 4 | 2900

|

32 | 2.68 | 3 | 65 | 50 |

| 25 | 20 | 43 | 3.17 | ||||||

| 30 | 18 | 46 | 3.20 | ||||||

| 65FSB-32 | 15 | 34 | 5.5 | 2900

|

42 | 3.31 | 3 | ||

| 25 | 32 | 56 | 3.89 | ||||||

| 30 | 28 | 58 | 3.95 | ||||||

| 80FSB-20 | 35 | 22 | 5.5 | 2900

|

55 | 3.82 | 3 | 80 | 65 |

| 50 | 20 | 65 | 4.19 | ||||||

| 60 | 17 | 63 | 4.41 | ||||||

| 80FSB-30 | 35 | 34 | 7.5 | 2900

|

58 | 5.59 | 3.5 | ||

| 50 | 32 | 64 | 6.81 | ||||||

| 60 | 28 | 60 | 7.63 | ||||||

| 80FSB-40 | 35 | 42 | 11 | 2900

|

53 | 7.56 | 3.5 | 80 | 50 |

| 50 | 40 | 63 | 8.65 | ||||||

| 60 | 36 | 60 | 9.81 | ||||||

| 80FSB-50 | 35 | 52 | 15 | 2900

|

55 | 9.02 | 3.5 | ||

| 50 | 50 | 63 | 10.81 | ||||||

| 60 | 45 | 55 | 13.38 | ||||||

| 80FSB-55 | 35 | 56 | 18.5 | 2900

|

50 | 10.68 | 4 | ||

| 50 | 55 | 60 | 12.49 | ||||||

| 60 | 48 | 55 | 14.27 | ||||||

| 100FSB-32 | 80 | 34 | 15 | 2900

|

65 | 11.40 | 3.5 | 100 | 80 |

| 100 | 32 | 70 | 12.46 | ||||||

| 121 | 28 | 65 | 14.20 | ||||||

| 40FSB-15 (D) | 3.5 | 15 | 3 | 2900

|

21 | 0.68 | 3 | 40 | 32 |

| 5 | 15 | 26 | 0.79 | ||||||

| 8 | 10 | 18 | 1.21 | ||||||

| 40FSB-20(D) | 6 | 23 | 3 | 2900

|

30 | 1.25 | 3 | ||

| 10 | 20 | 42 | 1.30 | ||||||

| 12 | 17 | 38 | 1.46 | ||||||

| 40FSB-30(D) | 6 | 32 | 3 | 2900 | 22 | 2.38 | 3 | ||

| 10 | 30 | 31 | 2.64 | ||||||

| 12 | 28 | 32 | 2.86 | ||||||

| 65FSB-32(D) | 15 | 34 | 5.5 | 2900 | 42 | 3.31 | 3.5 | 65 | 50 |

| 25 | 32 | 56 | 3.89 | ||||||

| 30 | 28 | 58 | 3.95 | ||||||