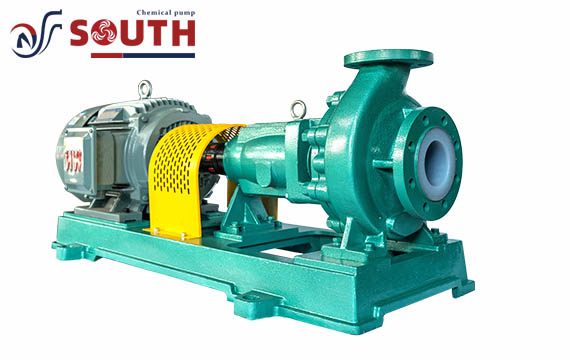

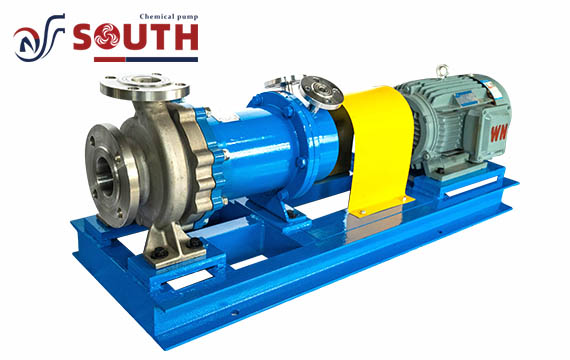

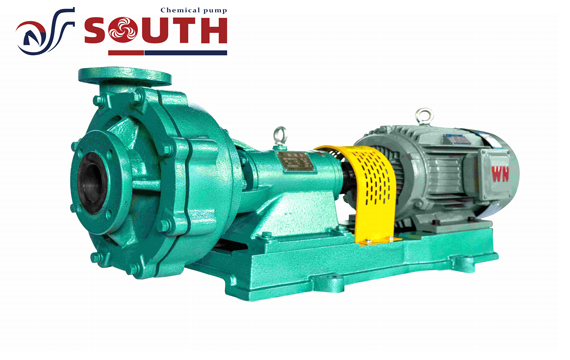

Single stage single suction lining fluorine plastic chemical centrifugal pump adopts the most advanced lining fluorine technology in China, and the company’s lining fluorine technology is a representative of the domestic advanced level, so this pump has extremely strong corrosion resistance.

Transporting corrosive fluids such as sulfuric acid, hydrochloric acid, and strong bases is not a problem. the biomedical industry, chemical industry, and new energy industry are all particularly suitable.

single stage single suction lining fluorine plastic chemical centrifugal pump’s flow capacity range is 1.6m³-2600m³, pump head range is 5m-130m, it can withstand high temperature of -20℃-180℃。

The inlet and outlet of the pumps are reinforced with special materials smooth operation, and the service life is very long, is a performance, quality, efficiency are very good pump.

Designed instruction of Lining fluorine plastic chemical centrifugal pump

The horizontal fluoroplastic centrifugal pump is designed according to international standards, integrating advanced non-metallic pump technology. The pump body features a metal shell lined with fluoropolymer (such as F46, PFA), while the pump cover, impeller, and shaft sleeve are constructed from fluoroplastic with metal inserts, formed through comprehensive sintering processes. The external shaft seal employs a high-performance bellows mechanical seal, with static components made from 99.9% alumina or silicon carbide rings, and reinforced by four fluoropolymer sealing materials, offering exceptional corrosion resistance. The inlet and outlet of the pump are reinforced with cast steel to enhance the durability and performance of the bearings. Practical application has demonstrated that this pump provides excellent resistance to corrosion and abrasion, withstands high temperatures, resists aging, and maintains high mechanical strength. The design also ensures smooth operation, structural integrity, advanced sealing capabilities, ease of disassembly, and a long service life.

Characteristics of fluorine plastic chemical centrifugal pumps

Capable of handling a variety of chemical substances, including different concentrations of sulfuric acid, phosphoric acid, acetic acid, and other strong acids. Also suitable for transporting strong alkalis, oxidizers, reducing agents, and highly corrosive substances like sodium hypochlorite. This pump is designed to resist corrosion from all types of stainless-steel materials, serving as a cost-effective alternative to pumps made from expensive materials such as titanium or Hastelloy alloys.

Advantages of Centrifugal Pumps

Excellent Corrosion Resistance: Made with high-quality fluoroplastic materials, offering exceptional corrosion resistance.

High-Temperature Resistance: Designed to effectively withstand high-temperature operating environments.

High Mechanical Strength: The robust structure provides outstanding mechanical strength and reliability.

Smooth Operation: Ensures stable operation with reduced vibration and noise.

Long Service Life: High-quality materials and advanced manufacturing techniques extend the pump’s lifespan.

Application areas of centrifugal pumps

Biopharmaceuticals: Utilized in the transport and circulation of pharmaceutical products, including injection solutions and other medical fluids.

Petrochemicals: Used for the transportation of crude oil, petroleum products, chemical raw materials, chemical products, and liquefied gases.

Power Generation: Centrifugal pumps play a crucial role in circulating water systems, water supply networks, and cooling systems.

Mining and Metallurgy: Essential for transferring various corrosive liquids, high-temperature substances, and slurries containing large particles and high concentrations. Pumps are necessary for draining mines, as well as supplying water during mineral processing, smelting, and rolling operations.

Centrifugal pump performance parameters of the table

| Model No | Flow Capacity

(m3/h) |

Pump Head

(m) |

Motor Power

(KW) |

Rotating Speed

(r/min) |

Efficiency

(%) |

Shaft power

(KW) |

NPSH(m) | Diameter(mm) | |

| Inlet | outlet | ||||||||

| IHF40-25-125 | 4 | 23 | 1.5 | 2900 | 38% | 0.7 |

2.5 |

40 | 25 |

| 6 | 20 | 40% | 0.8 | ||||||

| 8 | 18.5 | 42% | 1.0 | ||||||

| 2 | 5.5 | 0.55 | 1450 | 30% | 0.1 | 2.5 | |||

| 3 | 5 | 34% | 0.1 | ||||||

| 4 | 4.5 | 35% | 0.1 | ||||||

|

IHF40-25-160 |

4 | 34 | 2.2 | 2900 | 31% | 1.2 | 3 | ||

| 6 | 32 | 33% | 1.6 | ||||||

| 8 | 28 | 37% | 1.6 | ||||||

| 2 | 9 | 0.55 | 1450 | 24% | 0.2 | 3 | |||

| 3 | 8 | 27% | 0.2 | ||||||

| 4 | 7 | 29% | 0.3 | ||||||

| IHF40-25-200 | 4 | 52 | 4 | 2900 | 22% | 2.6 | 3 | ||

| 6 | 50 | 28% | 2.9 | ||||||

| 8 | 48 | 32% | 3.3 | ||||||

| 2 | 13.5 | 0.75 | 1450 | 20% | 0.4 | 3 | |||

| 3 | 12.5 | 23% | 0.4 | ||||||

| 4 | 12 | 25% | 0.5 | ||||||

| IHF40-25-250 | 4 | 82 | 7.5 | 2900 | 23% | 3.9 | 4.5 | ||

| 6 | 80 | 27% | 4.8 | ||||||

| 8 | 78 | 30% | 5.7 | ||||||

| 2 | 20.5 |

1.5 |

1450 |

22% | 0.5 | 4.5 | |||

| 3 | 20 | 25% | 0.7 | ||||||

| 4 | 19.5 | 28% | 0.8 | ||||||

| IHF50-32-125 | 10 | 23 |

2.2 |

2900 |

51% | 1.2 | 3 | 50 | 32 |

| 12.5 | 20 | 55% | 1.2 | ||||||

| 15 | 18.5 | 58% | 1.3 | ||||||

| 5 | 5.5 |

0.55 |

1450 |

47% | 0.2 | 3 | |||

| 6.3 | 5 | 50% | 0.2 | ||||||

| 8 | 4.5 | 52% | 0.2 | ||||||

| IHF50-32-160 | 10 | 34 |

4 |

2900 |

43% | 2.2 | 3 | ||

| 12.5 | 32 | 46% | 2.1 | ||||||

| 15 | 28 | 48% | 2.4 | ||||||

| 5 | 9 |

0.55 |

1450 |

39% | 0.3 | 3 | |||

| 6.3 | 8 | 40% | 0.3 | ||||||

| 8 | 7 | 42% | 0.4 | ||||||

| IHF50-32-200 | 8 | 52 |

7.5 |

2900 |

37% | 3.1 | 3 | ||

| 12.5 | 50 | 39% | 4.4 | ||||||

| 17 | 48 | 40% | 5.6 | ||||||

| 5 | 13.5 |

1.1 |

1450 |

32% | 0.6 | 3 | |||

| 6.3 | 12.5 | 33% | 0.7 | ||||||

| 8 | 12 | 35% | 0.7 | ||||||

| IHF50-32-250 | 10 | 82 |

15 |

2900 |

35% | 6.4 | 4.5 | ||

| 12.5 | 80 | 38% | 7.2 | ||||||

| 15 | 78 | 41% | 7.8 | ||||||

| 5 | 20.5 |

1.5 |

1450 |

32% | 0.9 | 4.5 | |||

| 6.3 | 20 | 34% | 1.0 | ||||||

| 8 | 19.5 | 36% | 1.2 | ||||||

| IHF65-50-125 | 15 | 23 | 3 | 2950 | 60% | 1.6 | 3.5 | 65 | 50 |

| 25 | 20 | 62% | 2.2 | ||||||

| 30 | 18.5 | 63% | 2.4 | ||||||

| 7.5 | 5.5 | 0.55 | 1450 | 53% | 2.0 | 3.5 | |||

| 12.5 | 5 | 54% | 0.3 | ||||||

| 15 | 4.5 | 56% | 0.3 | ||||||

| IHF65-50-160 | 15 | 34 | 5.5 | 2900 | 45% | 3.1 | 3.5 | ||

| 25 | 32 | 49% | 4.4 | ||||||

| 30 | 28 | 50% | 4.6 | ||||||

| 7.5 | 9 | 1.1 | 1450 | 48% | 0.4 | 3.5 | |||

| 12.5 | 8 | 51% | 0.5 | ||||||

| 15 | 7 | 53% | 0.5 | ||||||

| IHF65-40-200 | 15 | 52 | 11 | 2900 | 50% | 4.3 | 3.5

|

65 | 40 |

| 25 | 50 | 52% | 6.6 | ||||||

| 30 | 48 | 55% | 7.1 | ||||||

| 7.5 | 13.5 | 1.5 | 1450 | 46% | 0.6 | 3.5

|

|||

| 12.5 | 12.5 | 48% | 0.9 | ||||||

| 15 | 12 | 50% | 1.0 | ||||||

| IHF65-40-250 | 15 | 82 | 18.5 | 2900 | 49% | 6.8 | 3.5

|

||

| 25 | 80 | 51% | 10.7 | ||||||

| 30 | 78 | 52% | 12.3 | ||||||

| 7.5 | 20.5 | 3 | 1450 | 40% | 1.0 | 3.5 | |||

| 12.5 | 20 | 43% | 1.6 | ||||||

| 15 | 19.5 | 45% | 1.8 | ||||||

| IHF80-65-125 | 40 | 23 | 5.5 | 2900 | 68% | 3.7 | 4 | 80 | 65 |

| 50 | 20 | 70% | 3.9 | ||||||

| 60 | 18.5 | 72% | 4.2 | ||||||

| 15 | 5.5 | 1.1 | 1450 | 64% | 0.4 | 4 | |||

| 25 | 5 | 67% | 0.5 | ||||||

| 30 | 4.5 | 68% | 0.7 | ||||||

| IHF80-65-160 | 40 | 34 | 11 | 2900 | 64% | 5.8 | 4 | ||

| 50 | 32 | 67% | 6.5 | ||||||

| 60 | 28 | 69% | 7.2 | ||||||

| 15 | 9 | 1.5 | 1450 | 60% | 0.6 | 4 | |||

| 25 | 8 | 62% | 0.9 | ||||||

| 30 | 7 | 63% | 1.1 | ||||||

| IHF80-50-200 | 35 | 52 | 15 | 2900 | 60% | 8.3 | 4 | 80 | 50 |

| 50 | 50 | 63% | 10.8 | ||||||

| 60 | 48 | 65% | 12.1 | ||||||

| 15 | 13.5 | 2.2 | 1450 | 54% | 1.0 | 4 | |||

| 25 | 12.5 | 57% | 1.5 | ||||||

| 30 | 12 | 60% | 1.6 | ||||||