South Pump Factory, a professional magnetic pump manufacturer, offers tailored solutions with ample inventory and timely delivery, ensuring reliable fluid transfer for industrial progress.

Mag Pump Overview:

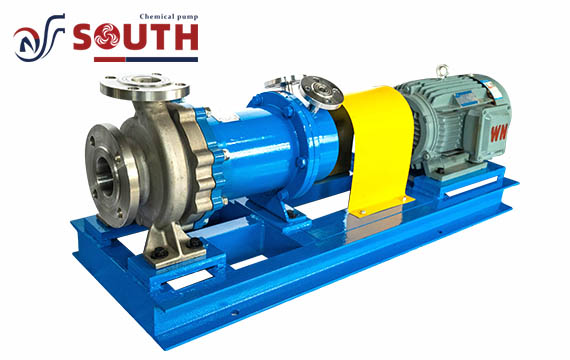

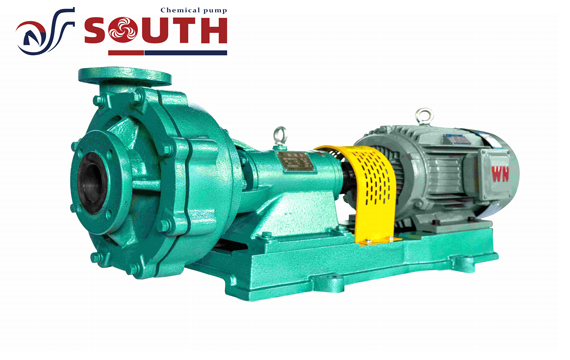

NMZ type magnetic drive self-priming pump (referred to as NMZ magnetic self-priming pump) is a new type of completely non-leakage corrosion-resistant pump developed on the basis of the existing magnetic pumps in the market according to the present user and market demand of our company.

NMZ type magnetic drive self-priming pump (NMZ for short) is a new type of completely non-leakage corrosion-resistant pump developed by our company according to the current user and market demand, combined with the existing magnetic pump on the market. It is mainly composed of electric motor, magnetic coupling and corrosion-resistant centrifugal pump.

It uses magnetic coupling to transfer power and is completely leakage-free. Characterized by the use of the motor to drive the magnetic actuator of the outer magnet steel rotation, the magnetic line of force through the gap and isolation sleeve, acting on the inner magnet steel.

When the motor rotates the outer magnet, the magnetic lines of force pass through the gap and the spacer and act on the inner magnet to synchronize the rotation of the pump shaft with the motor and transmit the torque without contact. At the power input end of the pump shaft, the liquid is sealed in the static isolation sleeve.

At the power input end of the pump shaft, as the liquid is sealed in the static isolation sleeve, there is no dynamic sealing, thus eliminating the phenomenon of running, risking, dripping and leaking which is inevitable in the petrochemical industry, and realizing no leakage at all.

Magentic Pump Description:

* Adopts API685 and HG/T2730 standards, the pump interface size is in line with the replacement of ZX, ZW and other chemical self-priming pumps, good compatibility, high efficiency, low vibration.

Good compatibility, high efficiency and low vibration.

* The pump adopts NdFeB permanent magnet as internal and external magnets, which has high magnetic efficiency and high temperature resistance.

* According to the technical requirements, the pumps are designed in split type, and the heat preservation device can be added for the crystallization medium.

* The building block structure is very easy to disassemble and maintain, which greatly reduces the professional requirements for maintenance personnel.

* can be equipped with idling protector according to user’s requirements to avoid damage caused by idling.

* Absolute no leakage completely solves the leakage problem of sealed pumps, and is also the best product to replace shielded pumps.

* It is also the best product to replace the shielded pump. It is committed to the safe transportation of corrosive and precious fluids.

Applications of Mag Pump:

Application: environmental protection, petroleum, chemical, food, biopharmaceutical, electric power, metallurgy, aerospace and other industries, such as oil refineries, ethylene plants, natural gas processing plants, chemical plants, pharmaceuticals and other industries.

Processing plants, chemical plants, pharmaceutical plants, nuclear fuel plants, nuclear power plants and so on.

Applicable processes: clean, flammable, explosive, volatile, toxic, valuable liquids and other requirements of no leakage and the medium does not allow the sealing of the occasion of pollution.

Material of Stainless steel magnetic self-priming pump:

Pump overflow parts according to the use of working conditions and user requirements can be respectively 304, 304L, 302, 321, 316, 316L, 904, titanium alloy, nickel alloy and other types of corrosion-resistant materials.

base alloy and other types of corrosion-resistant materials. If there are special requirements, the unit can be designed and manufactured according to the working conditions.A

About South Pump Factory

Your Trusted Experts in Magnetic Pump Manufacturing

In the pursuit of high efficiency, environmental protection and stable operation of the industrial era, we, as a professional manufacturing plant in the field of magnetic pumps, with excellent technical strength and rich experience in the industry, tailor-made high-quality magnetic pump products for you.

Professional factory, excellent quality

We know that professionalism is the cornerstone of quality. Therefore, we have gathered a research and development team composed of industry elites, constantly exploring and innovating, and devoting ourselves to the refinement and breakthrough of magnetic pump technology. From design, material selection to manufacturing and testing, every step of the process strictly follows international standards to ensure that each magnetic pump can achieve optimal performance to meet your diverse industrial needs.

Sufficient inventory, worry-free supply

In the face of the rapidly changing market demand, we have established a huge storage system to ensure that all kinds of magnetic pump products in stock. Whether it is a standard model or customized products, we can respond quickly, timely delivery, to provide uninterrupted support for your production line. Worry-free inventory makes your project progress smoother, without fear of supply cycle. Choosing us is choosing a reliable partner. Let’s work together to create a better future for industrial fluid transfer!

Our warehouse is fully stocked, we will ensure that your order is shipped within a week, customized magnetic pumps will be shipped within 2-3 weeks, the delivery time will only be ahead of schedule will not be delayed!