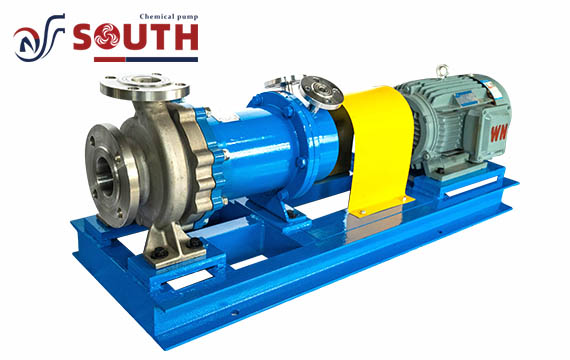

The split-type insulated stainless steel magnetic pumps, developed to meet user and market demands, are innovative, leak-free, and corrosion-resistant.

Overview:

*NMLEW split-type double-insulated magnetic drive centrifugal pump (NMLEW magnetic pump for short) and NMLSW split-type three-insulated magnetic drive centrifugal pump (NMLSW magnetic pump for short), are our company according to the current user and market demand, combined with the existing magnetic drive on the market.

*NMLEW split type double insulated magnetic centrifugal pump (NMLEW for short) and NMLSW split type triple insulated magnetic centrifugal pump (NMLSW for short) are new types of completely leak-free and corrosion-resistant magnetic pumps developed by our company on the basis of existing magnetic pumps in the market according to the current user and market demand.

*NMLSW magnetic pump is a new type of corrosion-resistant pump with no leakage. It is mainly composed of electric motor, magnetic coupling and heat preservation type corrosion resistant centrifugal pump, which utilizes magnetic coupling to transmit power and is completely leakage-free.

It utilizes magnetic coupling to transmit power and is completely leakage-free. Characterized by the use of electric motor to drive the magnetic actuator of the outer magnetic steel rotation, the magnetic line of force through the gap and isolation sleeve, acting on the inner magnetic steel, so that the pump shaft and pump shaft with a leakage-free corrosion-resistant pump.

*When the electric motor rotates the outer magnet, the magnetic lines of force pass through the gap and the isolation sleeve and act on the inner magnet to synchronize the rotation of the pump shaft with the electric motor and transmit torque without contact. At the power input end of the pump shaft, there is no dynamic seal because the liquid is enclosed in the static isolation sleeve.

*At the power input end of the pump shaft, as the liquid is enclosed in the static isolation sleeve, there is no dynamic sealing, thus eliminating the phenomenon of running, risking, dripping and leaking which is inevitable in the petrochemical industry, and realizing no leakage at all.

Product introduction:

* This series of pumps adopts ISO2858 and HG/T2730 standards, and the pump interface dimensions are in line with the replacement of IH, CZ and other chemical pumps, with good compatibility, high efficiency and low vibration.

High efficiency and low vibration.

* NMLEW series double insulated high magnetic stainless steel magnetic pump adopts high temperature cobalt material as inner and outer magnets, with high magnetic efficiency and small temperature coefficient.

In the shell and pump cover parts to increase the special insulation layer, specifically for easy crystallization of the insulation medium, at the same time for high temperature media above 200 degrees, the use of metal wound gaskets (code NMLEW).

At the same time, for high temperature medium above 200 degrees, metal-wound gasket (code NMLEWD) is used for sealing.

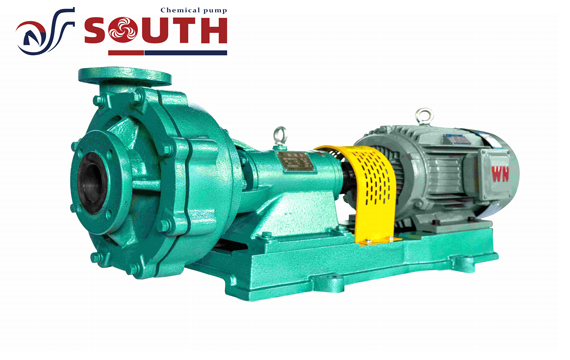

* NMLSW series triple-insulated stainless steel magnetic pump is based on NMLEW series double-insulated stainless steel magnetic pump, with special insulation layer added to the casing and pump cover as well as the isolation sleeve.

NMLSW series triple insulated stainless steel magnetic pump is based on NMLEW series double insulated stainless steel magnetic pump, with special insulating layer in the shell and pump cover as well as isolation sleeve part, which is specially used for the insulated medium that is easy to crystallize and needs insulation.

At the same time, for high temperature medium above 200 degrees, metal wound gasket (code NMLSWD) is used for sealing.

* The block structure is very easy to disassemble and repair, greatly reducing the professional requirements for maintenance personnel.

* According to the user’s requirements, we can configure idling protector and temperature control monitor to avoid the pump damage caused by idling and so on.

* Absolute no leakage completely solves the leakage problem of sealed pumps and is the best product to replace shielded pumps.

It is also the best product to replace the shielded pump. It is committed to the safe transportation of corrosive and precious fluids.

Magnetic Pmup Usage:

Application: environmental protection, petroleum, chemical, food, biopharmaceutical, electric power, metallurgy, aerospace and other industries, such as oil refineries, ethylene plants, natural gas processing plants, various chemical plants, pharmaceuticals and other industries.

Processing plants, chemical plants, pharmaceutical plants, nuclear fuel plants, nuclear power plants and so on.

Applicable processes: clean, flammable, explosive, volatile, toxic, valuable liquids and other requirements of no leakage and the medium does not allow the sealing of the occasion of pollution.

Mag Pump Material:

Pump overflow parts according to the use of working conditions and user requirements can be respectively 304, 304L, 302, 321, 316, 316L, 904, titanium alloy, nickel alloy and other types of corrosion-resistant materials.

Base alloy and other types of corrosion-resistant materials. If there are special requirements, the unit can be designed and manufactured according to the working conditions.