The ZMD Series Fluoroplastic Magnetic Self-priming Pumps are innovative products that combine the benefits of magnetic pumps and self-priming pumps. With a temperature range of -20℃ to 150℃ and a flow rate of 3m³/h to 250m³/h, they offer self-priming capabilities up to 2-4 meters.

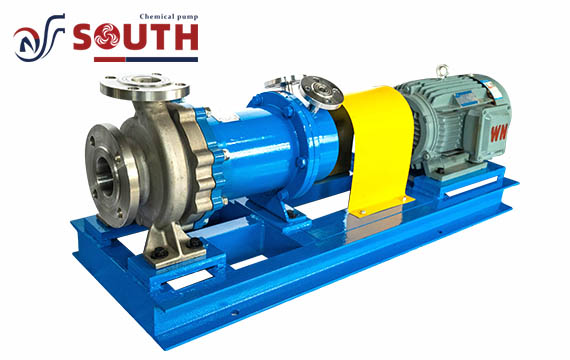

Overview of Magnetic Chemical Transfer Pump:

ZMD fluorine plastic magnetic self-priming pump is my company absorb the magnetic pump and self-priming pumps have their own characteristics, joint research and development of a number of research units, this series of pumps collection of magnetic pumps all the good characteristics, and the biggest advantage that can be self-priming, general self-priming height of up to 2-4 meters, a full combination of self-priming pumps and magnetic pumps have all the advantages of self-priming, both with the function of self-priming, but also the abolition of the shaft seal, the use of magnetic coupling indirect transmission, completely eliminating dripping and leakage. Transmission, completely eliminating the phenomenon of dripping.

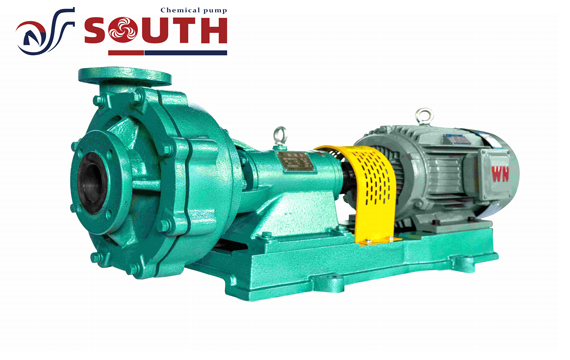

Uses of Self-Priming Mag Pump:

ZMD fluorine plastic magnetic self-priming pump is widely used in petrochemical, non-ferrous metal smelting pesticides, acid and alkali, paper, pickling process, rare earth separation, electroplating, electronics, chemical foils and other industries to absorb the transport of corrosive liquids lower than the pump installation position below the magnetic pump varieties of the structure of the most innovative products, high efficiency and energy saving, safe and practical.

Installation and Maintenance of Mag Pump:

- According to the size of the foundation, make a good concrete foundation and bury the ground bolts;

- Pumps and motors should be checked before installation, each part should be free of damage, and there should be no debris in the pump;

- Place the unit on the foundation, put a pair of wedge pads between the base plate and the foundation, and adjust the wedge pads to find the level of the pump;

- After adjusting, tighten the ground bolt;

- The suction and discharge pipelines of the pump are supported by another bracket;

- The installation is completed, the last hand turn the coupling, check whether there is no rubbing phenomenon, rotation is easy, even without stringing phenomena;

- The installation is finished;

- To prevent debris from entering the pump, a filter should be set at the inlet, and the filtering area should be larger than the cross-sectional area of the pipeline 3~4 times;

- High head pump in the export pipeline should also be installed backstop valve to prevent sudden shutdown of the water hammer damage;

- Must ensure that the installation height of the pump in line with the pump’s cavitation margin, and take into account the loss of piping and media temperature.

How to Start and Run a Magnetic Pump:

- Before driving the pump should be filled with the conveyed liquid (such as in the case of suction) close the outlet gate valve connected to the power supply;

- Connect the power supply, correctly check the pump steering according to the direction of the instruction plate is correct;

- The unit test run 5 ~ 10 minutes, such as no anomalies can be put into operation;

- When shutting down, the gate valve of the outlet should be closed first, and then cut off the power supply;

- When disassembling, first flush the pump body with water until the corrosive medium in the pump body is completely clean;

- The replacement of pump parts, not with sharp objects, hard objects to hit the pump parts, should be cork cloth wrapped in wood lightly, remove the parts should be placed gently, the sealing surface of the face of the pump should be removed;

- The parts should be put gently and the sealing surface should be facing up.